[continued from part 3]

The dangers of desktop studies

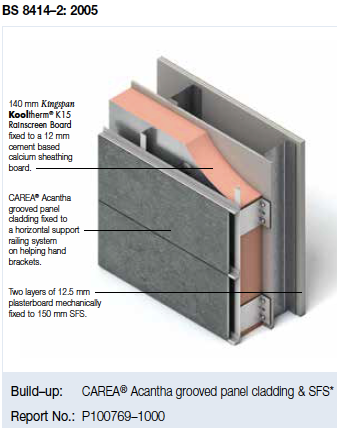

Kingspan give summary details of seven tests to BS 8414 of systems incorporating Kooltherm K15. In five cases, the outermost layer is formed from a material of limited combustibility. Of the two build-ups with combustible outer cladding, one had CAREA® Acantha panels, whose Reaction to Fire rating is EN 13501-1 Class B-s1, d0. The manufacturer states that their composition is 90% minerals and 10% binding resin.

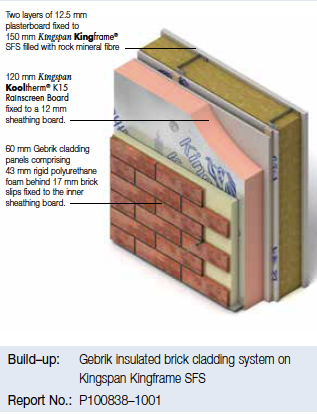

Another build-up was with the Gebrik insulated cladding system, which consists of brick slips cast into PUR foam. Its EN 13501-1 Class fire rating is B-s1, d0 according to the RIBA Product Selector, but B-s2, d0 according to BBA 07/4429. No cavity is visible between the outer cladding and the Koolterm K15 boards:

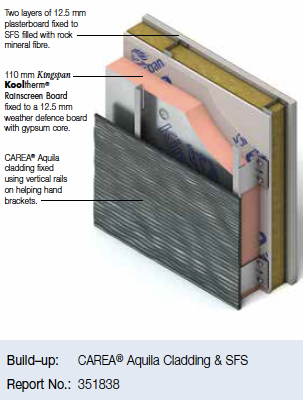

Kingspan give summary details of a further twelve facade systems which have been successfully assessed on the basis of a Desktop Study. At least two of these have a combustible outer cladding. One employs CAREA® Aquila panels:

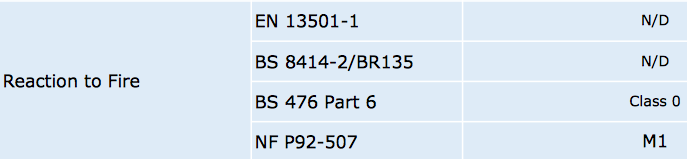

The panels are 4-5 mm in thickness, whereas CAREA® Acantha panels are 14-16 mm in thickness. Whereas CAREA® Acantha panels are EN 13501-1 Class B, the EN 13501-1 Class is not determined for Aquila panels: 1

It is national Class 0, but there is some evidence (Section on ‘Correlation of European and National Standards, and see also the Comments) that this is a less stringent category than Euro Class B. On what basis, then was the conclusion reached in the Desktop Report that this system would have passed a BS 8414/BR 135 test? We do not know, because the reports are confidential.

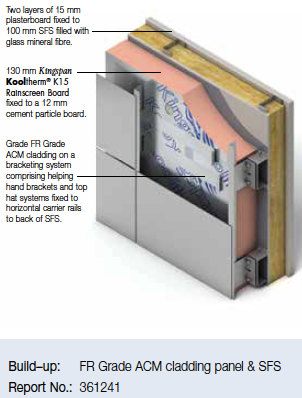

The other system with combustible cladding features FR ACM panels:

The recent DCLG BS 8414 test reports on cladding systems with FR ACM report the Calorific Value of FR ACM as more than 13.5 MJ/kg, more than four times the maximum value for a Euro Class A2 material of limited combustibility. Reynobond declare (Section on ‘Fire Classifications) a 70% mineral content for their FR ACM panels, which may be contrasted with the 90% mineral content of the CAREA® Acantha panels which were successfully tested to BS 8414. On what basis was the conclusion reached in the Desktop Report that this system would pass such a test?

A system with FR ACM panels and PIR boards failed its recent DCLG test to BS 8414/BR 135 by a fairly narrow margin, with flame spread above the test apparatus after 25 minutes (p. 14), 5 minutes before the fire load was due to be extinguished. A system with FR ACM panels and mineral wool insulation passed its recent DCLG test, but also by quite a narrow margin, a temperature rise of 600° being recorded at level 2 after about 20 minutes (p. 35), 5 minutes too late for it to count as a fail under the BR 135 criteria. Phenolic boards are generally considered to have better fire behaviour than PIR boards, but would nevertheless surely be closer to PIR than mineral wool in fire performance. The evidence of the DCLG tests points to a moderately high probability that a system with FR ACM and phenolic boards would fail such a test.

Chris Cook reported on 1 July 2017 that Newsnight had obtained two Desktop Studies which each gave an opinion concerning a system incorporating FR ACM panels and a Kingspan product (certainly Kooltherm K15), that it would pass a BS 8414/BR 135 test if it were to take one. An expert who examined the reports is quoted as saying that they:

appeared to extrapolate an apple into an orange.

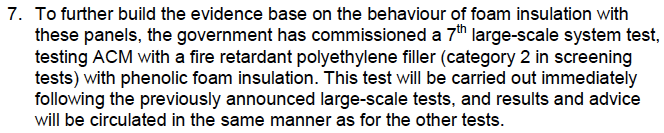

I am glad, therefore, that the DCLG announced on 8 August 2017 that it will conduct an additional large scale test of a phenolic plus FR ACM system:

the position of the bre, 2016

A striking example of the ambiguity currently surrounding the regulatory system for external cladding is provided by Diane Marshall’s report of a presentation by Stephen Howard, the BRE’s Director of Fire Testing and Certification to the 2016 NHBC seminar on ‘Facades to Tall Buildings’.

Howard, she said, explained the methods of demonstrating compliance with:

the recommendation documents that support the UK Building Regulations.

What is meant here by the ‘Building Regulations’, and what is meant by the ‘recommendation documents’? I see two possibilities:

a) The ‘Building Regulations’ are the statutory Building Regulations 2010, and the ‘recommendation documents’ are the Approved Documents.

b) The ‘Building Regulations’ are the Approved Documents, and the ‘recommendation documents’ include BCA TGN 18.

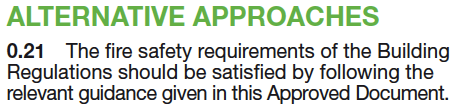

The Approved Documents themselves seem to refer to their own provisions as ‘guidance’ and consistently use the term ‘recommendations’ in connection with other codes and guides, and in particular with British Standards. Compare for example, in AD B2 0.21:

the relevant guidance given in this Approved Document

with:

Paragraph 1.4 of AD B2 shows the apparent distinction nicely, with the guidance being that the ‘recommendations’ of a British Standard ‘should’ be followed:

It is noteworthy also that BCA TGN 18 does offer its guidance as a recommendation only:

the BCA recommends three options for showing compliance

I have not found such language used in the Approved Documents.

Howard, according to Marshall, then outlined two ‘requirements’ contained in:

guidance in place for a number of years

What is this ‘guidance’? If it is that of the Approved Documents, why is that not said explicitly? Why ‘for a number of years’? The guidance on fire spread over external walls contained in AD B2 12.5 to 12.9 has been unchanged since 2006. The BCA Technical Guidance Note 18 was first issued in 2014. Why the vagueness? Which of these is it, or is it some other guidance?

It should be noted that Diane Marshall is one of the founding Directors of the Building Control Alliance Ltd., so could potentially have a certain bias towards giving prominence to the guidance it issues:

What then were the two requirements contained in the ‘recommendation documents’ or the ‘guidance in place for a number of years’? Marshall goes on to report Howard as saying that external wall build-ups to buildings over 18 should either:

a) use materials of ‘limited combustibility’ [Linear route]

OR

b) be tested to BS 8414/BR 135 [System route]:

So far as I can see, the BRE is adopting the BCA TGN 18 guidance for the Linear Route, and the AD B2 guidance for the System Route. In one way, this is commendable, since in each case the more stringent guidance is adopted. The two options they present are essentially those recommended by the EFRA Committee in 1999 and adopted by Scotland in 2005. This arrangement is reasonable and practicable and should ensure an adequate degree of fire safety for cladding systems.

But we are left with a complete muddle, with elements of more than one guidance being cherry-picked, so to say, and patched together into whatever new synthesis best suits the party concerned. The BRE can appear to be absolving itself, so to say, by associating itself with such stringent guidance. But it must surely have known that this was not the guidance either of the Approved Documents or of the BCA. To present it as if it were established guidance, only adds to the general confusion, in my opinion. Designers and contractors would be under no obligation to follow it, so little if anything is gained by such make-believe. It should also be noted that BRE operates what is (I have been informed) the only BS 8414 testing facility in the UK, and so could have a financial interest in:

a) choosing the more stringent version of the Linear Route, forcing an whole system route to compliance to be taken where the outer cladding is combustible, as well as when the insulation is combustible;

AND

b) not presenting Desktop Studies as a possible means of assessing the whole system, with the result that a BS 8414 test would be necessary.

the dclg prefers bca guidance to its own

It might be thought that where it comes to a conflict between Approved Document and BCA guidance, the Government guidance would have precedence. In the (vanishingly unlikely, in my opinion) event that there exists a Desktop Study of the Grenfell system undertaken before the cladding was installed on the tower, and giving a favourable opinion of it, a Court might still take the view that this bears little weight since the Approved Documents require an actual test to BS 8414.

The situation is complicated, however, by the remarkable fact that the DCLG itself has given its blessing, so to say, to the Desktop Study route to compliance, with a nod to BCA TGN 18, and in preference to the guidance of Approved Document B2, which the DCLG itself publishes.

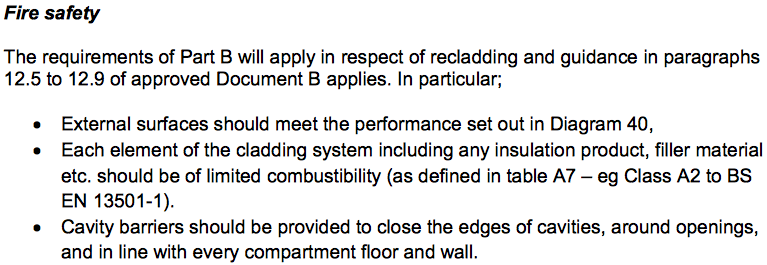

In its Circular Letter of 13 July 2017, the DCLG first summarises the Linear route to compliance in a way which I have discussed before (Section on Circular Letter):

It then describes the alternative AD B2 System route to compliance in an accurate way:

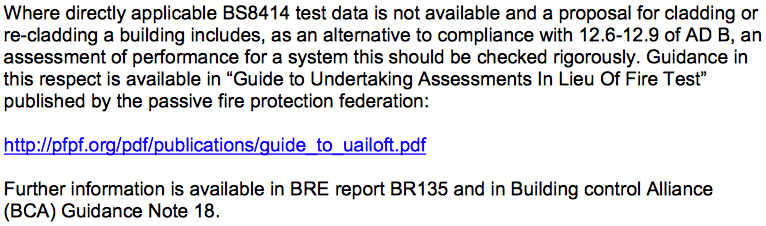

But then, astonishingly to my mind, it offers the Desktop Study route to those who are unwilling or unable to pay for an actual fire test. Where:

directly applicable BS8414 test data is not available

it does not, as one would expect, direct that such data be obtained so as to fulfil the requirements of the DCLG’s Approved Document. Instead, it directs that where a cladding proposal includes a Desktop Study in lieu of a real fire test:

this should be checked rigorously.

Reference is made to the Passive Fire Safety Federation’s ‘Guide to Undertaking Assessments In Lieu Of Fire Tests’, and to BR 135 and BCA TGN 18:

The PFPF document is about the general principles of undertaking assessments in lieu of fire tests, and does not give any specific guidance about carrying out an assessment in place of a BS 8414 test. BR 135 gives criteria to assess a real fire test to BS 8414 and makes no reference to conducting a desktop assessment in lieu of such a test. Indeed I have quoted BR 135 already to the effect that (p.19):

The classification applies only to the system as tested and detailed in the classification report.

For guidance then on how Desktop Studies should be ‘checked rigorously’, the recipients of the Circular Letter, including notably the Heads of Building Control in the Councils and the Approved Inspectors, are left with the terms of Option 3 of BCA TGN 18:

The report should be supported by test data from a … UKAS accredited testing body (BRE, Chiltern Fire or Warrington Fire) and so this option may not be of benefit if the products have not already been tested in multiple situations / arrangements. The report should also specifically reference the tests which have been carried out on the product.

Further to my comments in part 2, all this definitely tells us is that the fire specialist should make use of fire test data for the products incorporated in the system. Well, so I should hope. The one Desktop Study I have seen makes use of a combination of BS 8414 data for rather different systems, combined with the EN 13501-1 report on the outer panels of the proposed system. Since these outer panels in this case were Euro Class B, this EN 13501-1 report would have shown the behaviour of the panels when they were subjected to the SBI (Single Burning Item) EN 13823 test. This is a surface test, and gives only limited information of the behaviour of combustible panels in a real fire. It is this limitation that led to the introduction of the large-scale BS 8414 test. So what is the Government doing suddenly giving its approval by means of a Circular Letter to such an inadequate substitute for large-scale testing? And this in the immediate aftermath of the horror of Grenfell Tower! What a disgrace.

Andrew Chapman

Andrew, very good summing up about how this desktop study system is as full of holes as Emmenthal cheese. The reality is these desktop studies, without any real oversight, end up with the NHBC proclamations of 2016 allowing all Class 0/Euro Class B products. Who checks on these independent fire specialists, their qualifications, and the quality of their work? In fact who is checking on BRE and Exova? And when they make a nonsense desktop study allowing use of cheaper materials, what’s the betting it is then taken by other nearby firms as de facto approved and before you know that system is used on 10 other blocks?

Regarding the Acantha panels, it is interesting that these panels are 90% mineral yet these only reach Class B, yet the versions of the metal composite panels with 90% mineral cores reach Euro A2/limited combustibility- perhaps the metal facings in this case make the difference? You are right that the Class 0/Euro Class B panels and phenolic insulation passing a BS 8414 desktop study seems shaky given the tests with mineral wool insulation only just passed- hopefully these BS 8414 tests will resolve any doubt in this area. If it does fail, it will be interesting what will happen to all these old desktop studies i.e. somehow it is agreed they will all be voided, if not other fire specialists may continue to cite them.

Seeing as CAREA is a French company, I had a look on the French site, and these are the figures from their datasheets (all in the old French system?), not sure it gives you anything more, but here it is:

CAREA Acantha

https://carea-facade.fr/produits/acantha/

Classement au feu

M2 (M1 sur demande)

Masse Combustible 65 à 80 MJ/m²

CAREA Aquila

https://carea-facade.fr/produits/aquila/

Classement au feu

M2

Masse Combustible

standard = 40 à 50 MJ/m²

massif = 80 à 105 MJ/m²