(continued from part 1)

Booker and North’s main argument, as I understand it, is that:

- The 1999 ETRA Committee recommended that the BS 8414 large-scale system test should have been made mandatory for cladding systems.

- Our membership of the EU prevented this being done.

- If it had been done, the Grenfell Tower fire would not have happened.

In this post, I demonstrate that the ETRA Committee did not in fact recommend making the BS 8414 test mandatory. Instead they proposed two alternative routes to compliance:

a) through the use of non-combustible materials;

b) through the BS 8414 test.

I also show that Scotland did adopt a regulatory system of this type in 2005. Since Scotland is in the EU as much as England and Wales are, this in itself rather proves that membership of the EU presented no obstacle to the Westminster government adopting a similar system.

The 1999 eTra committee inquiry

Booker (1 July) begins his account (also here) with the 1999 House of Commons Environment, Transport and Regional Affairs (ETRA) Committee inquiry into the ‘Potential Risk of Fire Spread in Buildings via External Cladding Systems’ (Evidence, First Report, Government Response), which was launched after a man died in a fire in Irvine, Scotland. Booker:

We have to stop right there. EN 13501-1, which is the first part of the EN 13501 series, and the part that is referred to in the relevant part of the building regulations, was approved by the CEN on 15 November 2001:

and Peter Field made no mention of it, or indeed any other European standard, in his evidence to the Committee (see pages 15 – 18). He referred only to the British BS 476 fire test series, to the classification system associated with that series of standards, and to the large-scale test method which later became BS 8414.

How then did Booker mistakenly refer to EN 13501 as the ‘existing fire standard’ for 1999? It seems possible that he took it from Richard North’s blog post of 30 June, in which he had the Committee recommending in 2000 the replacement of ‘the existing European standard’:

Again, on 2 July, Richard North recounts what Booker had written the day before, almost verbatim, not realising that it was mistaken:

small-scale and large-scale tests

While Field did not refer at all to EN 13501-1, Booker is correct when he says that Field saw a need for a test of the cladding system as a whole, rather than relying only on separate material tests:

Field did indeed speak of a need to look at systems as a whole (Evidence, Q. 40):

Later (Q. 46) he referred to the current guidance which required Class 0 for surfaces above 18m and said that meeting that requirement would ‘not adequately identify the fire performance of the whole system’:

At Q. 71, he referred to the fact that a Class 0 is achieved through ‘spread of flame’ testing:

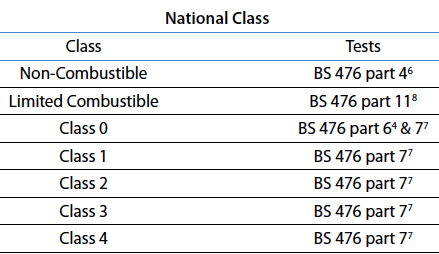

Class 0 is achieved by means of BS 476 parts 7 ‘Surface Spread of Flame’ and 6 ‘Fire Propagation’ (in that order). At that time it was the 1992 edition of Approved Document B that was in force, as stated in the Government Response, p. vi:

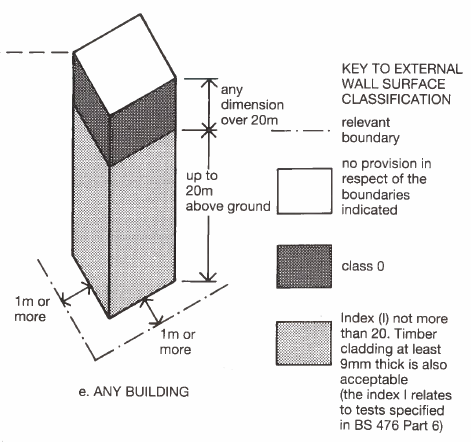

In that edition, the requirements for high buildings not adjacent to another building are given in Diagram 36.e:

It can be seen that surfaces above 20m must be Class 0, and that there is no alternative European class. In 12.7, attention is brought to the risk of using combustible materials for the ‘cladding framework’ or for thermal insulation. A definite requirement for ‘limited combustibility’ is reserved for ‘insulation material’:

Limited combustibility is defined in Appendix A in terms of the BS 476 part 11 750° C furnace test with the same criteria as the national class column has in Table A7 today. As was the case for the surface requirement, there was no European class alternative:

The 1992 Table A7 may be found here (p. 5 of pdf). With no alternative route to compliance through large-scale testing available at that time, insulation material used above 20m had to be of limited combustibility. I do not think that any polymer-based insulation board could pass the part 11 (750° C) test. A 2011 Technical Note by the Centre for Window and Cladding Technology confirms that: 1

The only commonly used insulation material that will satisfy the definition of limited combustibility is mineral wool.

At the same time, it was even clearer than it is today that rainscreen cladding panels did not have to be of limited combustibility, according to the Approved Document guidelines. They only had to be Class 0, and so did not have to take the part 11 furnace test.

It may be worth highlighting with a diagram that ‘limited combustibility’ is a higher class than Class 0 (BS 476-4 is another 750° C furnace test, similar to 476-11):

With adequate requirements already in place for insulation, it is thus understandable that Field focussed (Q. 71 above) on the weakness of the Class 0 requirement for other cladding components. The dangers of the Class 0 rating with respect to composite materials had been highlighted earlier in the day (Evidence, Q. 13) by Dr Moore, Chairman of the Technical Committee of the Fire Safety Development Group:

you can cover up … a combustible material with a metal sheet … which … still allows the fire to burn and destroy the plastic material underneath … you may even meet the requirements for a Class ‘0’ material, but the actual product can still contribute to the fire…

It is not small-scale tests per se that may allow dangerous cladding systems to slip through the net. I do not think that any system which passed the 750° C furnace tests would present any danger at all. The problem, as Dr Moore brought to the attention of the Committee in 1999, is specifically with surface tests conducted on materials with a non-combustible surface and combustible core.

What did the MPs recommend?

Booker claimed that the Committee wanted to replace the European standard EN 13501 with the British large-scale test standard BS 8414. North, who was at least aware of the national standard BS 476, claimed (30 June, see quotation above) that it wanted to replace both existing standards with what became BS 8414, making the latter ‘mandatory’. Making allowance for their mistake (which is only a matter of getting the chronology wrong by a couple of years) their point can survive as a claim that the Committee wanted to replace the existing small-scale material tests with the large-scale system test.

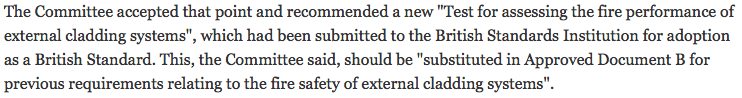

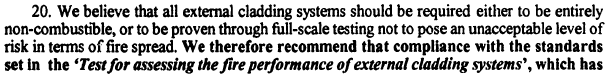

On 28 June, North used a quotation from the Committee’s Conclusions to make it appear that they wanted the new large large-scale system test to replace completely the existing requirements:

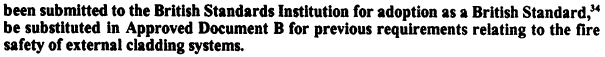

The quotation is accurate but selective. The advice of the Committee, read as a whole, was that there should be two routes to compliance. Either all the elements should be non-combustible, or the system should undergo the large-scale test:

Admittedly, the second sentence in itself supports North and Booker’s contention. But the first sentence with its ‘either-or’ alternatives makes it clear that the Committee actually had two routes to compliance in mind. After all, if none of the components are combustible, then the system as a whole will certainly be non-combustible, and it would be a waste of time and effort to test it.

[ADDED 8 January 2018.

I am not sure whether any distinction need be drawn between what the Committee said they believed should be done, and what they ‘recommended’ should be done. It is odd that only the second part of their two part proposal is:

a) repeated in the second sentence in paragraph 20;

b) put in bold type;

c) included in the ‘Summary of Conclusions and Recommendations.

Tragically, in the light of the Grenfell Tower fire, the Government heeded only the second part of the Committee’s advice, instituting a new route for compliance through large-scale testing, and thus weakening the cladding regulations by making it possible to employ combustible insulation above 18 metres. In their Response to the Committee’s Report, the Government addressed only the points made in the Summary, and brazenly ignored the proposal to introduce a non-combustibility requirement for all elements of cladding systems that had not been subjected to the large-scale test.

END OF ADDED SECTION.]

On a point of detail, I suspect that the Committee could have set the bar for components a little lower at ‘limited combustibility’ and still provided a route for system safety without large-scale system tests. Some inorganic products have a low percentage of organic content which could potentially prevent them being classed as ‘non-combustible’, but which would not present a significant fire danger. System tests are probably only needed where one or more of the components have a substantial combustible content.

scotland

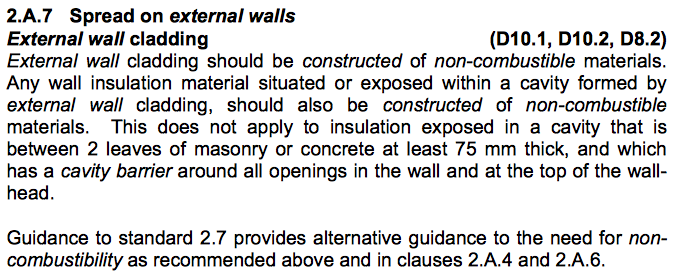

What the Committee proposed was incorporated into the Scottish building regulation guidance in 2005. The Technical Handbook (Domestic) of that year included an Annex (p. 163 of pdf) with additional guidance for high rise domestic buildings:

External wall cladding was to be constructed (p. 164 of pdf) of non-combustible materials:

External wall cladding should be constructed of non-combustible materials.

An exception was made only for insulation material sandwiched between masonry or concrete and with cavity barriers in place. Reference was made to an alternative route to compliance:

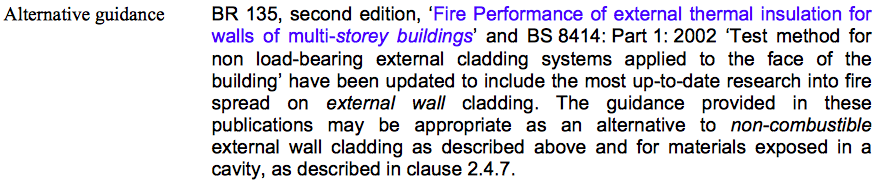

This alternative route (2.7.1, p. 120 of pdf) was to test to BS 8414 according to the criteria contained in BRE 135:

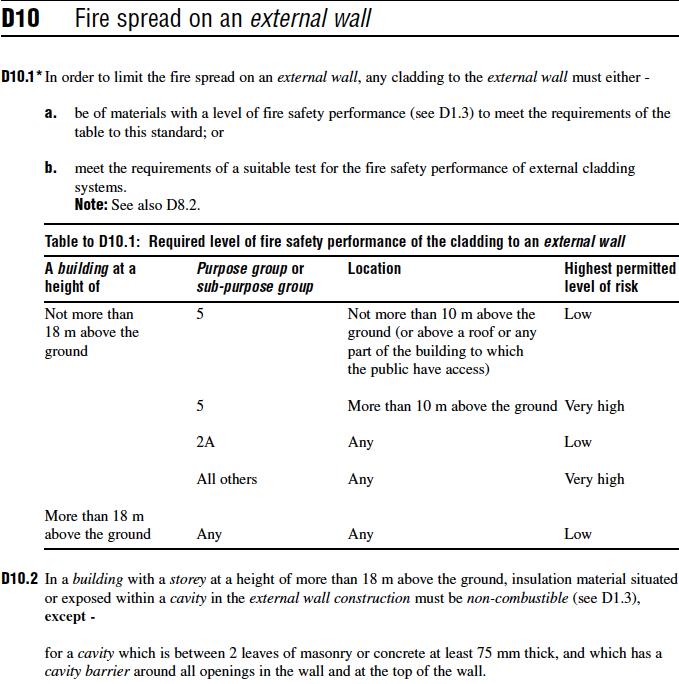

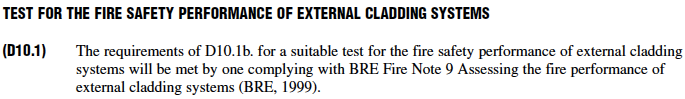

Previously, from 2002 to 2005, the sixth amendment of the Technical Standards had been in force. Cladding on buildings above 18 m was to be composed of ‘low risk’ materials, while insulation materials were to be non-combustible, with the same exception as in the current Scottish guidance. Alternatively (D10.1b. p. 84 of pdf), the cladding system could meet the requirements of a suitable test:

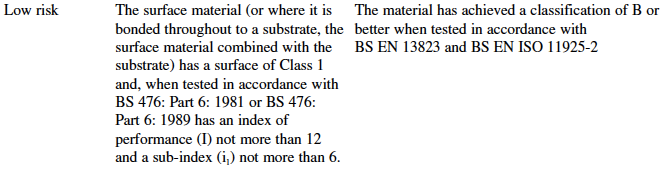

‘Low risk’ materials were defined in the following terms:

The criteria to be met with regard to BS 476 are exactly the same as those defined as Class 0 in Approved Document B. The requirement with regard to the European Standards is likewise the same as that for the upper storeys of high buildings AD B2. So far as I can see, there were no restrictions on materials used at heights below 18m for residential buildings (Purpose group 1) in Scotland, whereas in England and Wales there are material requirements for the lower storeys of high buildings (AD B2, Table 40.e).

The alternative route was to comply with BRE Fire Note 9, the forerunner to the BS 8414/ BRE 135 system test method:

To summarise, in 2005 Scotland raised its cladding standards from a level very similar to that of the current Approved Document B2, to that recommended by the Commons Committee. We now turn to the Westminster government response to those recommendations.

government response to committee recommendations

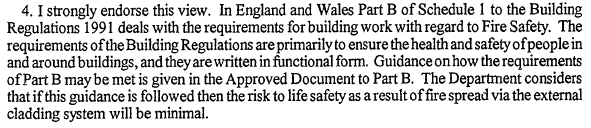

The Committee had reported in December 1999, urging a reconsideration of the guidance on external wall cladding systems. To its shame, the Government responded in March 2000 by claiming that the existing guidance was satisfactory. If it was followed, they claimed:

then the risk to life safety as a result of fire spread via the external cladding system will be minimal.

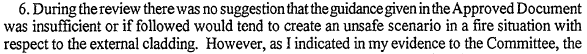

The Government said (para. 5) that Approved Document B (‘fire safety’) had been reviewed by experts in a Working Group of the Building Regulations Advisory Committee. There had been no suggestion that the guidance with respect to external cladding was insufficient:

The Fire Research Station (now part of the BRE), however, had been tasked to review the guidance it had given in 1988 in the first edition of BR 135 ‘Fire performance of external thermal insulation for walls of multi-storey buildings’. The revised guidance was expected to be available by September 2001. It was in fact published as the 2nd edition of BR 135 in 2003, and the authors were Sarah Colwell, who had appeared with Field before the Committee (Evidence, p. 15), and Brian Martin. I don’t have access to this edition but I do have the 2013 third edition by Colwell and Tony Baker. It does not seem to engage with the specific requirement for cladding materials contained in Approved Document B. There is no direct mention of Class 0, for example, as the requirement for cladding panels. It does however point out the potential dangers of combustible panels with ‘good surface spread of flame characteristics’ (as would be indicated by a Class 0 rating):

Once the panels become involved in a fire, Colwell and Baker observe, they have the potential to:

generate falling debris, add to the overall fire load, and provide a route for fire to propagate up the outside of the building.

Well quite. And if so, does this not present more than a ‘minimal risk’ to the safety of those living in high buildings beyond the reach of fire service external equipment? Field (and presumably Colwell) were in the room on 20 July 1999 when Bob Moore of the FSDG had warned (p. 7) of the dangers of composite panels. They no doubt read the FSDG’s memorandum to the Committee (Evidence, pp 5-7) which spoke of:

widespread concern amongst many fire fighters

about the safety of external cladding systems incorporating:

metal-faced foam plastics.

The core of PE ACM panels is not foam, but the principle seems to be the same. The FSDG believed that this subject of composite panels was:

still being reviewed by the DETR

and they urged:

more stringent controls.

How can it be then that the Working Group of the Building Regulations Advisory Committee had heard ‘no suggestion’ that the existing guidance which allowed combustible Class 0 panels was insufficient? That is a question that the Grenfell inquiry, or the Courts, must answer.

And the EU?

On 4 July, in a post entitled ‘Brexit: Grenfell Tower – blood on their hands’, with the hands in question being those of the European Union, Richard North claimed that if the EU had introduced tougher fire tests for cladding, instead of ‘blocking national attempts to make such testing mandatory’, then ‘the Grenfell fire would not have occurred:

The EU, North claims, had ‘failed to take the necessary action to prevent [the Grenfell Tower fire] happening’. As a result, they were ‘as guilty as any party for the fire’:

This is really quite outrageous. I want to state categorically that the EU bears no responsibility at all for our Grenfell Tower fire. It is our own fault, and we the British are to blame for it. We have failed in our duty to ensure the safety of those who live in our country, whether they be British or foreign.

One way of proving that the introduction of the new European harmonised fire classification standard EN 13501-1 could not have prevented the strengthening of regulation in England and Wales, is simply to point out that Scotland did bring in more stringent regulation. In my next post, I will explain what this European standard is, and explain the flaws in North and Booker’s argument, to the best of my admittedly limited ability.

Andrew Chapman

Notes:

- ‘Fire performance of curtain walls and rainscreens’ (Technical Note No. 73, Centre for Window & Cladding Technology). Now replaced by Technical Note No. 98. ↩

You know, you might be the only person who’s actually understood that ENs are not EU.

Great post again Andrew. Very enlightening detail on the EFRA Committee and Peter Field’s comments. It seemed clear even back in 1999 that Class 0 was a hopelessly out of date and ineffectual test as to the fire safety of a product, yet it is still used and touted as a safety feature on numerous insulation brochures. I am of the firm opinion that this rating has given false reassurance to members of the public and the building profession who have used this in good faith.

Thanks, John. I suppose that the Class 0 tests (BS 476 7 & 6) are fine for their purpose, and probably give a good indication of surface properties. As you point out, for insulation products – I guess you have the boards like Celotex RS5000 in mind – where you have a combustible core and only a very thin facing – the Class 0 rating may give false reassurance.