The Government testing program

The Grenfell Tower calamity highlighted the possible danger of employing combustible cladding on high rise buildings. Of the two main cladding components, the aluminium polyethylene (PE) composite rainscreen outer cladding panels, and the polyisocyanurate (PIR) insulation boards, it was the ACM panels that have generally been thought – probably rightly in my view, as I have argued previously – to have been the primary cause of the disastrous rapid spread of the fire over the external surface of the building.

The Government acted with commendable speed and efficiency by requiring Local Authorities and Housing Associations to identify by end of day 19 June any ACM panels in use on their high rise buildings, and to send in samples for testing.

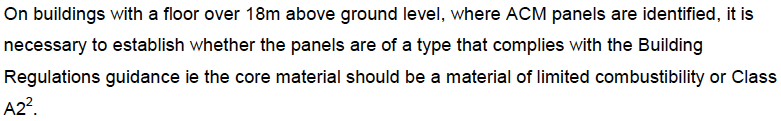

In its letter to the Chief Executives, the Department for Communities and Local Government (DCLG) claimed that to be compliant with ‘Building Regulations guidance’, the core of the panels should be composed of a material of ‘limited combustibility’, as defined in Approved Document B2 at Table A7, or be Euro Class A2 or better:

I outlined the Approved Document guidance for cladding systems in an earlier post. In brief, in AD B2 at 12.5, two routes to compliance are offered:

i) through adherence to the requirements of sub-sections 12.6-9 or;

ii) through large-scale system testing to BS 8414.

The DCLG, in its letter, was in effect assuming that the second route had not been taken, so that it was the requirements of 12.6 to 12.9 that were to be satisfied. In summary, 12.6 specifies that:

external surfaces over 18m should be national Class 0 or Euro Class B or better;

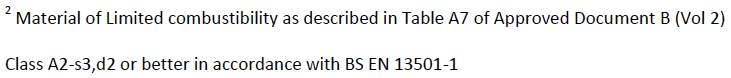

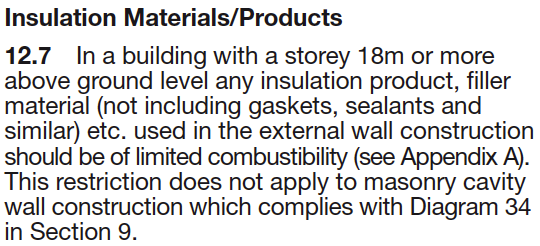

while 12.7 requires that for buildings over 18m:

insulation products, filler material etc should be of ‘limited combustibility’ as defined in the Table A7 mentioned in the DCLG’s letter. A material or product must either be 99% or more inorganic, or pass a 750° C furnace test (BS 476 part 11 or part 4), or have an incombustible core, or be Euro Class A2 or better.

I concluded in an earlier post that of the two main components of the Grenfell Tower system, only the Celotex RS5000 insulation boards were in breach of the Approved Document guidance, since it was only these that were covered by 12.7. The Reynobond PE cladding panels, not being an insulation product, and having a Class B rating, were in compliance with the relevant section, which is 12.6.

It is easy to see the difficulty for the government of admitting that the polyethylene cored cladding panels were compliant with the Approved Document guidance. It had been their responsibility to ensure that the regulations were fit for purpose and did not permit dangerous products to be used. These panels were certainly dangerous, in the use to which they were put. If a way could be found to assert that the regulations did not in fact permit the panels to be used, then this could potentially allow them to escape culpability in this regard.

Moreover, it was no doubt felt to be imperative to get any similar panels off the nations high rise buildings as soon as possible. It would probably be easier to force immediate action if the panels could be deemed to be non-compliant with the official guidance, than if it were admitted that they had been designed and installed in accord with it.

It is not particularly surprising, therefore, that the DCLG is currently pretending (if I may be so bold) that combustible ACM panels are in breach of the Approved Document guidance. In this post, I critically analyse the ways in which the Department has attempted to justify their position.

interpretation of sub-section 12.7

The main issue is the interpretation of sub-section 12.7, which reads:

While it may be of secondary importance from a legal point of view, 1 we may start with the heading, which suggests that sub-section 12.7 applies to insulation materials and products. If the heading is anything to go by, then ACM panels are not covered, since they are not insulation products.

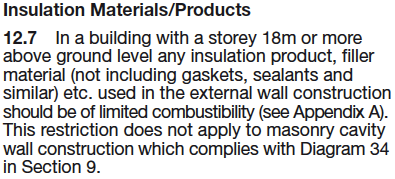

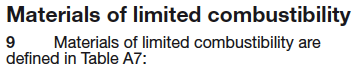

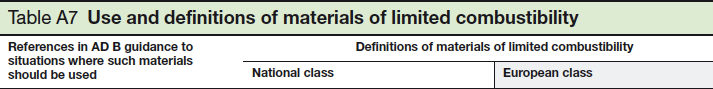

The extent of the coverage is stated more definitely in Appendix A. Paragraph 9 directs the reader to Table A7 for a definition of materials of limited combustibility:

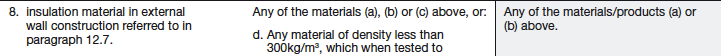

Row 8 of the table specifies that it is:

‘Insulation material in external wall construction’

that is covered by the limited combustibility requirement of paragraph 12.7:

Since the cladding panels are not any form of ‘insulation material’, they cannot be subject to the limited combustibility requirement. I have not personally seen this argument from Table A7 for exclusion of the panels advanced anywhere before. Its neglect may possibly account for the surprising degree of support found for one or both of the following two arguments for their inclusion.

In the text of 12.7, we find two categories of material and product that are brought under the ‘limited combustibility’ requirement, in addition to ‘insulation product[s]’: ‘filler material’, and whatever is intended to be included in the et cetera. There are two corresponding potential arguments for including ACM panels under 12.7:

a) The ACM core is a filler material;

b) the et cetera covers all elements of the cladding system.

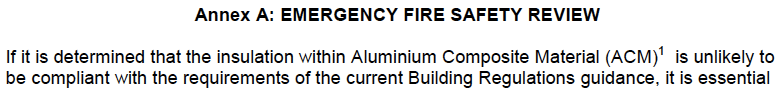

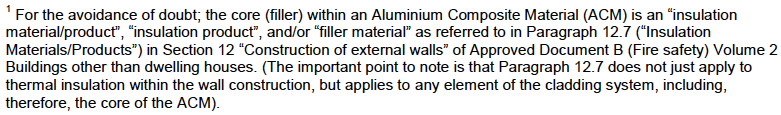

On 22 June in a further letter to the same recipients, the DCLG appeared to make use of both of these arguments simultaneously in a footnote:

First, the ACM core is referred to as a ‘filler’, implying that it may be regarded as a ‘filler material’. 2 Second, it is claimed, without any explanation, that 12.7 applies to ‘any element of the cladding system’. Logically, it seems to me, the only way that it can do so is if the et cetera extends to include any element.

explanatory note, 30 June

On 30 June the DCLG issued a Note to explain the programme that was underway to check residential tower blocks for ACM cladding and, where ACM panels were found, to test samples for compliance to Building Regulations guidance. In the Summary, reliance is placed on the idea that the ACM core is a ‘filler material’:

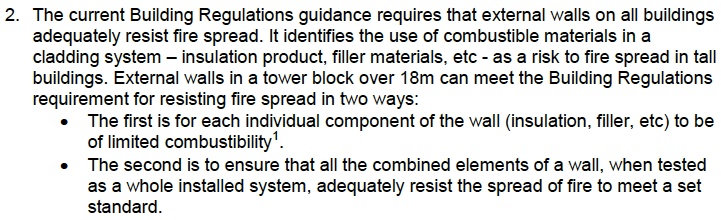

Then, in a remarkable passage, the Department shifts its ground from the Approved Document guidance to the statutory requirement underlying it:

This needs to be taken one sentence at a time:

In summary, the Building Regulations guidance sets a requirement for external walls on all buildings not to allow fire spread.

This is not accurate. The requirement is ‘set’ by the statutory Building Regulations 2010, as the Approved Document itself makes clear at its Part B4, which corresponds to Article B4 of Schedule 1 to the statute:

The Approved Document does not set the requirement, it provides guidance on how to meet it.

And it identifies the use of combustible materials in a cladding system – insulation product, filler materials, etc – as a risk to fire spread in tall buildings.

Here the DCLG is on firmer ground. AD B2 states at 12.5:

This general statement about possible risk is then followed by specific guidance about how to reduce the risk to what was considered to be safe levels. 12.6 begins:

and Diagram 40 specifies national Class 0 or Euro Class B, not the higher ‘limited combustibility’ grades. In 12.5, the Approved Document is alerting the reader to risk, not imposing a ban on combustible materials.

The Department’s view, supported by expert and legal advice, is that external walls in a tower block can meet the Building Regulations requirement for resisting fire spread in two ways, set out in more detail in Annex A.

The DCLG now bring in ‘expert and legal’ support for the view that the Building Regulations requirement can be met in two ways. The statutory requirement, remember, is that cladding should ‘adequately resist the spread of fires over the walls’. What follows therefore is their experts’ own guidance about how the requirement should be met. The DCLG are not necessarily claiming that these experts believe that this is the current Approved Document guidance.

The first is for each individual component of the wall (insulation, filler, etc) to be of limited combustibility, and to each meet set standards for this.

The second is to ensure that all the combined elements of a wall, when tested as whole system, have sufficient fire spread resistance to meet a set standard.

The Department and their advisors say that ‘each individual component of the wall’ should be of limited combustibility, or the whole system should be tested. In my opinion, that is excellent guidance. 3 Again, they do not directly say that this is the Approved Document guidance.

There is a nod to the Approved Document with the parenthesis and its ‘insulation, filler, etc’, which perhaps creates an impression that it is still the guidance that is under discussion. The implication may be that the et cetera in 12.7 extends to include ‘each individual component of the wall’, whether insulation product or not.

In the next section of the Explanatory Note of 30 June, the DCLG come back to their contention that the ACM core is a ‘filler’:

‘Core’ and ‘filler’ are treated in the first sentence as interchangeable terms. I have included the whole paragraph because it is important to note, in passing, that the government were not aware at that time of any cladding systems with PE ACM or FR (fire-resistant) ACM panels that had passed a BS 8414 large-scale system test. It seems to me that if there had been such a successful test, the government would have been informed about it. Surely any manufacturer would make every effort to prevent their product being stripped off buildings and regarded as a risk to human safety.

It follows that from a practical point of view, it is only the individual component route to compliance that is open at this time. The question is what that route requires, according to Approved Document B2.

The next paragraph of the Explanatory Note draws attention to the Class 0 surface rating, and once again equates the ACM core with ‘filler material’:

I have to say that this strikes me as disingenuous. It is hardly a ‘view’ that Class 0 is a surface rating. Class 0 is achieved through the surface tests BS 476 parts 6 and 7, and so is certainly a surface rating. Even less is it a ‘view’ that Class 0 does not meet a ‘limited combustibility’ requirement. That’s like a University taking the ‘view’ that your grade C doesn’t meet the requirements of grade B. That’s not a view, that’s a fact. What is being sneaked in under cover, as it were, is the Department’s view that there is a limited combustibility requirement for the ACM core.

And notice that the DCLG does not say here that this is the Approved Document requirement. They may merely be referring back to the previous paragraph where they created this requirement from ‘expert and legal advice’, ex nihilo as it were.

At paragraph 20, the DCLG gives the conclusions of the panel of experts whose appointment had been announced on 27 June, and who had met for the first time on 29 June:

Here the panel, including Dr Peter Bonfield, Chief Executive of the Building Research Establishment, show themselves willing to put their name to the idea that the ACM core is the ‘filler’ of the panel. I am surprised by this as I find it difficult to see how this view can be supported, for reasons I explain below.

In Annex A come further references to ‘filler material in the core’ (para. A.3) and ‘ACM filler’ (para. A.7). Then, just when we seemed to have settled on the view that the ACM core is a ‘filler material’ and therefore covered by AD B2 12.7, there comes a surprise in A.10:

Compliance with Approved Document guidance may be achieved, it is said, by meeting ‘the criteria for limited combustibility set out in … ADB … 12.5 to 12.9’. But the criterion for 12.6 is national Class 0 or Euro Class B, the attainment of which, as the DCLG reminded us at paragraph 13, does not mean that the material is of ‘limited combustibility’. The criterion for limited combustibility is in paragraph 12.7. So why refer to ‘the criteria for limited combustibility set out in [12.5-9]’, unless it is to airbrush over, as it were, the reality that there are in fact two very different criteria contained in these paragraphs, with very different implications for human life and safety?

Is the ACM core a ‘filler material’?

We have seen that the Explanatory Note of 30 June made repeated references to the ACM core being a ‘filler’ or ‘filler material’, with the implication that it would therefore be covered by the ‘limited combustibility’ requirement of AD B2 12.7. But is the ACM core really a ‘filler’ or ‘filler material’?

The relevant definition in the Oxford English dictionary is:

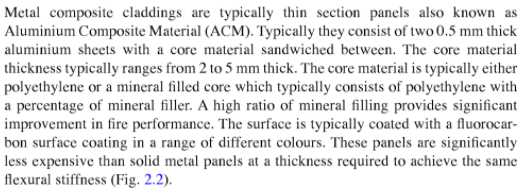

The first idea is of filling in some physical space. This is certainly not what the polymer core of an ACM panel is doing. Its purpose, as described by Arconic, the manufacturer of Reynobond, is to add ‘strength and rigidity’ to the aluminium sheets. Moreover, it is chemically bonded (2.2.A, p. 3) to the sheets to form an integral unit; it is not just filling in the gap between them.

But how about the last idea in the OED definition of bringing something to a ‘required solidity’? The fact that a filler material may bring something to a required solidity does not mean that everything that brings something else to solidity is a filler material. The polymer core is not just filling up the bulk of the panels, but is a major structural component, it seems to me.

Perhaps the greatest difficulty with the proposed nomenclature is that the term ‘filler’ or ‘filler’ material is widely used in connection with polymer composites, but refers to inorganic materials added to the polymer, rather than to the polymer itself. The point is nicely illustrated by this description of ACM panels, which discusses the use of mineral ‘fillers’ added to the polyethylene core (p. 4):

The Encyclopedia of Polymer Science and Technology describes fillers as:

particulate materials added to polymers in order to improve the physical properties and/or to reduce the cost of the composite.

Examples of fillers are carbon black, calcium carbonate, talc and silica. They are added to polymers to increase their stiffness and their fire resistance (p. 123):

What, then, is meant by the term ‘filler materials’ in AD B2 12.7? The heading distinguishes between insulation ‘products’ and insulation ‘materials’. The text speaks first of any insulation ‘product’, then of any filler ‘material’. Is it possible that a distinction is being made between formed products like insulation boards, and loose materials like insulation balls or fibre used to fill cavities? But in that case, what would the ‘etc’ be?

[ADDED 18 December 2018] According to ‘John’ in the comments below, ‘filler materials’ are ‘building material fillers’

used for any pre existing cracks or voids caused by damage, movement or shrinkage etc., as well as any cracks or damage caused by the refurbishment works.

Their application would I think be to masonry walls rather than to facades. ‘John’ gives two links to products from Corden Group (see ‘Joint Fillers’ here, and ‘Concrete Repair and Treatment’ here) and from Watco (here) as examples of what he means.

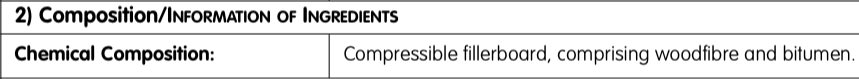

So far as I have been able to ascertain from their Material Safety Data Sheets and Technical Data Sheets, most of these products are combustible. Corden Fibrefill, for example, is said to be comprised of woodfibre and bitumen, both of which are combustible:

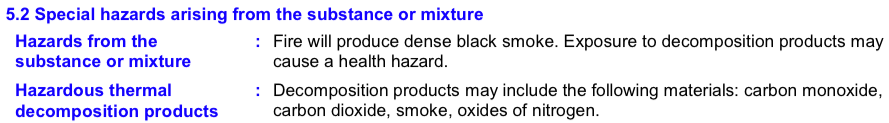

Watco Putty Patch produces ‘dense black smoke’ in a fire:

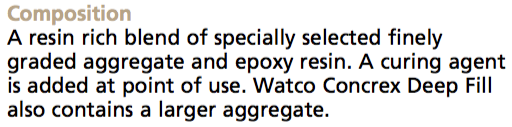

Watco’s Concrex Range is composed of a ‘resin rich’ blend of aggregate and epoxy resin:

and epoxy resin is combustible.

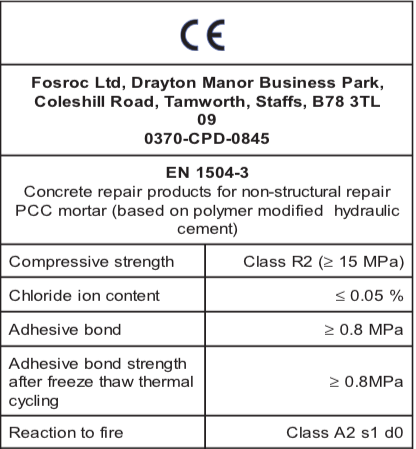

On the other hand, a mortar like Fosroc® Renderoc HB (here) is of limited combustibility, being EN 13501-1 Class A2:

It would then be suitable for use as a filler material on external walls over 18 m, if this is the correct interpretation of the term in paragraph 12.7.

An argument against this interpretation is that Table A7 specifies that it is ‘insulation material’ that is covered by the limited combustibility requirement. Also, the heading to paragraph 12.7 seems to indicate that it is ‘Insulation Materials/Products’ that are covered. Filler materials of this sort, used to fill gaps and cracks, are not insulation products or materials, and are therefore not covered, would be the objection. It seems to me, however, that headings and names of categories provide a description of the main content that is covered and do not necessarily cover minor additional items. Fillers used for cracks and gaps would seem to be of relatively minor importance compared to insulation which extends across the whole external wall, and could perhaps have been added to paragraph 12.7 in response to concerns raised about combustible versions of these products, without provoking a change of heading or category name.

[END OF SECTION ADDED on 18 December 2017.]

circular letter on recladding, 13 july

On 13 July the DCLG sent a Circular Letter to building control bodies to give guidance to ensure that the recladding of buildings which had had ACM panels stripped off would be carried out in compliance with building regulations. Naturally, the letter carried a re-statement of what the building regulations require. The first route to compliance, through the use of appropriate individual components, was summarised as follows:

The first requirement is that of AD B2 12.6. It will be remembered that at heights over 18m the ‘external surfaces’ have to be national Class 0 or Euro Class B. Now a ‘surface’ has to be the surface of some product and it is that product which is tested to Class 0 or Class B. This means in effect that the outer cladding panels must be Class 0 or Class B or better.

The second requirement is the DCLG’s interpretation of AD B2 12.7. They claim that it requires that ‘each element’ of the cladding system should be of ‘limited combustibility’. Earlier we found the Department giving their view that the statutory requirement to adequately resist fire spread could be met this way. But now they are claiming that AD B2 12.7 actually says this. I show it again so that it is in front of us:

The only way in which this paragraph can be taken to cover ‘each element’ of any cladding system is if the et cetera covers everything other than insulation products or filler materials – apart, that is, from ‘gaskets and sealants and similar’, which are excluded. I see six problems with this:

- According to the paragraph’s heading, it covers only insulation products and materials.

- Table A7 confirms that only ‘insulation material’ is covered.

- It seems odd to include such a major element of the system as the rain screen cladding under the catch-all et cetera.

- [ADDED 18 December 2017 to provide links to further arguments in the following post of 18 August 2017.] The two leading commentaries on the building regulations, Knight’s Guide and Billington et al’s The Building Regulations consider the paragraph to be referring to insulation materials. (Next post, sections: Knight’s Guide; ‘The Building Regulations: Explained and Illustrated.)

- The Centre for Window and Cladding Technology’s Technical Note 73 of March 2011 understood the paragraph to cover ‘insulation and filler materials’ only. (Next post, section: CWCT Technical Note 73, March 2011). [END OF MATERIAL ADDED on 18 December 2017]

- If the paragraph had been intended to cover all elements – or all elements bar ‘gaskets, sealants and similar’ – it would have been a simple matter to say so in an unambiguous way. In 2005, for example, Scotland had revised its guidance to specify (with their ‘non-combustible’ having a similar meaning to the Approved Document’s ‘[of] limited combustibility’) that (p. 163 of pdf):

External wall cladding should be constructed of non-combustible materials.

Nothing could be simpler.

historical evidence

During the 1999 ETRA Committee enquiry into the ‘Potential Risk of Fire Spread in Buildings via External Cladding Systems’, the 1992 edition of Approved Document B was in force. The ‘limited combustibility’ requirement applied only to ‘insulation material’ (paragraph 12.7):

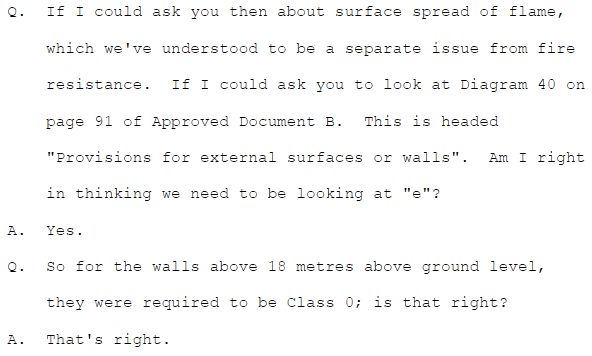

In the evidence to the enquiry there is never any suggestion that the cladding systems as a whole should be of limited combustibility. Rather, there was much discussion of the potential weakness of the actual requirement, which was that the cladding materials should be Class 0. For example, Dr Bob Moore of the Fire Safety Development Group warned of its dangers (Q. 13) with regard to composite products with a plastic core:

Likewise Dr Peter Field of the Building Research Establishment acknowledged (Q. 46) that the Class 0 rating might not in some circumstances ‘adequately identify the fire performance of a complete system’:

There was a consensus that Class 0 was the requirement for the outer panels.

lakanal house enquiry

At the 2013 Inquest into the deaths at the Lakanal House Fire of 2009, attention was drawn to the major refurbishments of 2006/2007, during which composite insulation panels were installed under the windows. 4 It was the 2002 version (2000 Edition incorporating Amendments of 2000 and 2002) of Approved Document B that was examined by the Court:

On Day 24 of the Inquest, the Coroner shifted the focus to features of the building that were of potential significance to the very rapid spread of the blaze (p. 3):

The first witness in this new phase of the Inquest was Dr David Crowder of the Building Research Establishment, who had been either lead or joint author of all four of the BRE’s reports concerning the fire (pp. 8-9). He described (p. 29) the external layers of the panels as being made of ‘paper-type’ materials bound together with a resin, while the core he believed to be ‘something similar to a polyurethane [PUR]’. The BRE had subjected (p. 141) a panel sample to BS 476 part 7 (Surface Spread of Flame), and found it to be Class 3 (p.143):

On Day 34 (5 March), Crowder indicated, in response to a question, that the relevant statutory requirement for the panels was Class 0 (p. 51):

On Day 40, Brian Martin of the DCLG gave evidence. He had previously worked for the BRE, where part of his job was to support the DCLG in preparing the 2006 edition of Approved Document B (p. 8):

He said (p. 34) that the external walls were required to be Class 0:

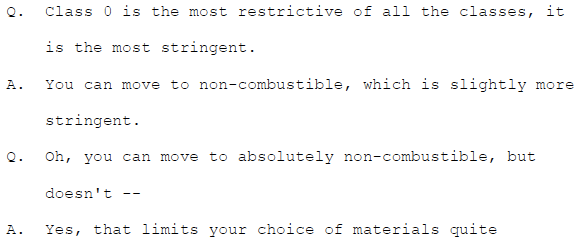

When it was put to him that Class 0 was the most restrictive class, he pointed out (p. 57-8) that it would be possible to move to what he called ‘non-combustible’, which would however limit the choice of materials:

This apparently makes it certain that Martin did not believe that the composite panels were subject to a requirement to be of a reaction to fire class any higher than Class 0.

Once more, in the narrative verdict for Catherine Hickman, it was stated that the composite panels had been required to be Class 0:

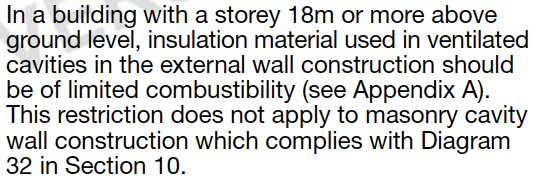

Since the composite panels contained insulation material, why was there apparently no suggestion during the Inquest that they should have been of ‘limited combustibility’? The answer seems to be that the 2002 version of Approved Document B2 required only that ‘insulation material in ventilated cavities’ had to be of ‘limited combustibility’ (para 13.7):

The insulation material in the composite panels at Lakanal was not in a ventilated cavity, and therefore did not have to be of limited combustibility.

The regulations were thus weaker than they had been in 1992. While previously the requirement for limited combustibility was limited to insulation material, now it was confined to insulation material used in a particular way. As in 1992, there was no mention of ‘filler material’ or of an et cetera, which could extend the coverage of the restriction beyond these narrow limits.

The 2006 edition

In the 2006 Edition of Approved Document B2, the external wall limited combustibility requirement took its current form:

Inside the front and back covers are listed the main changes from the 2000 edition which it replaced:

With regard to B4 (‘External Fire Spread’), there is no mention of a change in the limited combustibility requirement:

It seems to me that if the addition of the et cetera in what then became paragraph 12.7 had been intended to signify that all elements of the cladding system now had to be of limited combustibility, then this would have been considered a change worthy of mention amongst the ‘main changes’ listed in the new edition. That it was not so mentioned suggests that no such major extension of coverage was intended.

Likewise, if the addition of ‘filler material’ had been intended to bring ACM panels into the coverage of 12.7, this would surely have been thought worthy of mention, given how widespread was the use by then of ACM panels in external cladding systems.

DCLG Explanatory Note 20 July

The DCLG issued a further Note on 20 July to explain the large-scale testing of cladding systems to BS 8414 that is currently underway. As in paragraph 11 of the Explanatory Note of 30 June, it looks as though the Department may have resorted again to (what looks rather like) the clever ruse of shifting their ground mid-paragraph from the Building Regulations guidance to the (statutory) Building Regulations requirement:

As in paragraph 11 (30 June), they rightly say that the guidance identifies (AD B2, 12.5) combustible materials as presenting a ‘risk’ of fire spread in tall buildings.

Then they assert that the (statutory) Building Regulations requirement can be met either by:

- ensuring that ‘each individual component’ of the wall is of limited combustibility; or

- subjecting the whole cladding system to a large-scale test.

Quite so (with the proviso mentioned in my footnote 2). But notice that they do not definitely say that these are the two options presented by the guidance. All they are definitely saying, I think, is that these are the two ways of making sure the cladding adequately resists fire spread. In effect, if read in this way, this is what a DCLG statement of what the guidance should be.

That said, the most natural reading of the paragraph may still be that the third sentence beginning ‘External walls…’ is recounting further what the guidance says. I think most readers will take it that way. But this is not definitely stated, and the DCLG could potentially claim that it was not their intention to convey such a meaning.

And back to ‘filler’

Finally, in paragraph 4 of the Note of 20 July, the DCLG returns to the notion that the ACM core could be regarded as ‘filler material’:

Again, there is a touch of ambiguity. The parenthetical ‘or filler’ strikes me as less definite than ‘the filler’ would be. The DCLG could potentially claim, I think, that they only meant it as a possibility that the core could be regarded as filler material. But then again, it can be read as a more definite statement that the ACM core should be regarded as filler material for the purposes of 12.7.

Conclusions

The DCLG have been using two justifications for their position that combustible ACM panels are in breach of the Approved Document guidance:

- The ACM core is a ‘filler material’; and

- all elements of the cladding system are covered by 12.7.

They are thus employing redundancy. Either one of these justifications, if accepted, would be sufficient on its own. But if both fail, then no justification remains.

Logically, the only way that ‘all elements’ can be covered by 12.7 is if the et cetera extends from insulation products and filler materials to include everything else in the external wall construction. The DCLG have not made this case explicitly. Rather on two occasions, they have employed what looks like a sleight of hand. They have made a statement about the guidance, and then without drawing attention to the change of ground, asserted that the statutory requirement can be met by all elements of the cladding system being of limited combustibility.

It is generally accepted that the ACM panels, and the ACM core, are not an insulation product. As a result, there are three major difficulties with any attempt to pretend (please forgive my impertinence) that they are covered by 12.7:

i) The paragraph’s heading suggests that it is ‘Insulation Materials/Products’ that are the subject of the requirement contained within it.

ii) More definitely, Row 8 of Table A7 states that the limited combustibility requirement of 12.7 applies to ‘insulation material’.

iii) Prior to the 2006 edition, it is certain that the equivalent restriction applied only to ‘insulation material’, or even more narrowly to ‘insulation material in ventilated cavities’. If the change in wording in the 2006 edition had been intended to bring ACM cladding panels under its coverage, then surely this would have counted as a ‘Major Change’ to be included under that heading inside the front and back covers. But there is no mention of it there.

The idea that the ACM core is a filler material suffers from the additional major objection that it does not accord well with the concept of a ‘filler’. The ACM core is not just filling in a space, and nor is it bulking out the aluminium, in the way that a mineral filler may bulk out or even add properties to a polymer.

The idea that the et cetera was intended to extend to all elements of the cladding system suffers from its own additional major objection that if this had been the intention, it would have been very straightforward to say so. Only the previous year, Scotland had introduced a requirement that external wall cladding should be made of what it termed ‘non-combustible’ materials. The Westminster government could very simply have done something along the same lines, if it had desired to do so.

It should have done so in 2000, as the ETRA Committee recommended. That it did not is a disgrace and a shame, as there had been strong warnings in the evidence given to the Committee about the dangers of composite panels with a combustible core but good surface rating. Now is the time to admit our failures – of both Labour and Conservative Governments – and rectify them speedily. The DCLG’s current policy of employing what appears to be deliberate obfuscation to change the plain meaning of the text of paragraph 12.7 will not help at all in the process of healing and recovery from the Grenfell Tower disaster. Indeed, it is liable to hinder the adoption of the simple amendment that could extend its limited combustibility requirement to all elements of external wall construction. It could potentially also lead to misdirected attempts at prosecution, based on a supposed breach of the guidance in respect of the panels, which would end in failure when the text of the guidance was examined in Court.

That said, I would like to end where I began and commend the Government for their speedy action in addressing the danger of combustible ACM panels. That so many were stripped off in such a short time with a minimum of fuss in most cases should offer a ray of hope for our future.

Andrew Chapman

Notes:

- But probably not irrelevant. See, for example, with respect to legislation rather than guidance, here, here, and here. ↩

- The and/or implies the possibility that the core could be an insulation or product. It is never so regarded in practice, so far as I know. No manufacturer claims any secondary insulatory function for ACM panels, again so far as I am aware. ↩

- There is a question as to whether there is still a need for a national Class 0 or Euro Class B surface rating, for products which achieve ‘limited combustibility’ by the national class. Euro Class A2 automatically meets all the requirements of Euro Class B, but the same may not apply to the national ‘limited combustibility’ class. ↩

- Inquest, Day 24, p. 24, lines 19-23. Link. ↩

Andrew, excellent work, once again. I think the comments by Dr. David Crowder and Brian Martin at the Lakanal enquiry are the clincher here, absolutely no doubt they are saying that external cladding panels only have to meet Class 0, not limited combustibility, or non combustibility.

Of course the year after this, in June, 2014 we did have the announcement by the Building Control Alliance of Guidance Note 18, which restricted all materials in external cladding to limited combustibility, unless it passes BS 8414 by actual test or by newly introduced ‘desktop study’.

https://www.allerdale.gov.uk/downloads/bca_guidance_note_18_use_of_combustible_cladding_materials_on_residential_buildings.pdf

The attempt to describe the core of the ACM panels as filler is a clear nonsense, fillers are a reference to building material fillers, whether cement, PE foam or bitumen based.

Andrew, I thought you would be interested in this comparison of thermal conductivity (lambda values) of two types of insulation vs ACM cladding panels. It shows pretty conclusively that ACM rainscreen panels cannot be regarded as insulation material.

Insulation

Celotex RS5000 thermal conductivity is 0.021 W/mK

Rockwool thermal conductivity is 0.035 W/mK

ACM Rainscreen cladding panels

Alucobond PLUS 3mm thermal conductivity is 0.49 W/mK

Alpolic A2 and FR thermal conductivity is 0.45 W/mK

Reynobond PE 4mm has a thermal conductivity of 0.44 W/mK

Brilliant, thanks John for your understanding of ‘filler material’. Forgive my ignorance, but in what circumstances do they tend to be used in external wall construction? I suppose there might be a myriad occasions when one might want to fill in a gap or a hole for one reason or another, but I don’t have a clear picture of it.

So I guess the effect of the 2006 amendment was a shift from PE foam and bitumen (and any other combustibles) to cement (and any other non-combustibles).

Andrew

Hi Andrew. Fillers and sealants (the etc.?) would be used for any pre existing cracks or voids caused by damage, movement or shrinkage etc., as well as any cracks or damage caused by the refurbishment works. Products from these two companies will give an idea

http://www.corden-bssp.co.uk/our-products.php

http://www.watco.co.uk/repair/walls/wall-repair

I previously tried to post on here Andrew, but maybe got blocked for links- trying again. Fillers are simply used to fill cracks or gaps caused by movement or shrinkage/expansion or other damage to the masonry, occuring before or during the refurbishment process.

As you say, the DCLG are very much trying to obfuscate here, there really is no controversy as to what filler etc. is in this meaning in the Approved Document B. If you search for watco or corden fillers you get an idea of the sort of product.

Andrew, it’s possible that you could stretch that meaning to refer to filler or welding rods used in the welding of either metals or plastics. But still, it cannot be used in the sense of a fusion bonded core of a commercial product as in ACM or other composite panels such as VMZINC or Alpolic zinc/steel/titanium.

I am not sure why I hadn’t noticed this before, but there is a section that explicitly refers to these ‘thermoplastic CORES’ and NOT ‘fillers’ in Appendix F (pg. 145) of Approved Document B Vol 2, but it mostly concentrates on the risk these pose internally, which is, in hindsight, clearly a bad judgement. There is also a section in Appendix B (pg. 120) part 18 that could refer to external panels:

“A thermoplastic material in isolation can not be assumed to protect a substrate, when used as a lining to a wall or ceiling. The surface rating of both products must therefore reach the required classification. If however the thermoplastic material is fully bonded to a non-thermoplastic substrate, then only the surface rating of the composite will need to comply.”

John, thanks very much for the information on fillers. The ones I have looked at – eg Watco putty, Watco Concrex, Corden’s Fibrefill, seem to be combustible, judging by the Material Safety Data Sheets. It would be interesting to find one which is advertised as suitable for use on external walls over 18 m.

[ADDED 19 December 2017. I missed Corden’s Concrete Repair products, including Renderoc which is Euro Class A2: http://www.corden-bssp.co.uk/product/renderoc-hb More or less traditional mortars with little or no organic content will generally be suitable I think.]

Thanks also for pointing out Appendix F which as you say adds to the case that the ACM cores can not be described as filler material.

Andrew

John, with regard to your suggestion of 1 August that sealants are the et cetera, is this not ruled out by the first parenthesis in 12.7: ‘not including … sealants’?

Andrew