In my last post, I argued that the core of an ACM panel cannot reasonably be described as a filler material. The Government, and also to its shame the Building Research Establishment, have been doing precisely that, and as a consequence the new usage has passed to some extent into common parlance. But what is at issue is what the term ‘filler material’ meant at the time that the Grenfell Tower refurbishment was being planned and executed. I do not believe the term was ever used in a publicly available form to refer to the ACM core prior to the terrible tragedy of 14 June 2017, and I ended my last post by challenging the Government to produce even a single instance of such usage.

The point, to recap on previous posts, is that the Government is contending that the core of the ACM panels installed on Grenfell Tower, and in hundreds of high rise blocks in England and Wales (but not Northern Ireland 1) has long been required to be of limited combustibility, on the basis of paragraph 12.7 of Approved Document B2:

The clause rather obviously applies to insulation used in cladding systems rather than to the outer cladding, but our Government has been pretending (or so it seems to me) that the core of ACM panels is included under the requirement for two or three of three possible reasons:

i) The core is an insulation product or material; and/or

ii) the core is a filler material; and in any case

iii) all elements of the cladding system are included.

I have replied to each argument in three posts, in sections marked A to C. I maintain that:

A) The ACM core has no insulation function (here).

B) Only insulation, filler material and relatively minor items are covered (here).

C) The ACM core is not a filler material (here).

If the core is not a filler material, then the question naturally arises as to what is meant by ‘filler material’ in 12.7. I look first at what the term means in the construction industry in general, then at what filler materials are used in external wall construction in particular, and finally at its probable intended meaning in 12.7.

Filler materials in the construction industry

Travis Perkins is probably the largest distributor of general building materials to the construction industry. ‘Fillers‘ are one of hundreds of categories of products for sale on their web-site. Most of the products listed are of the type familiar to most as Polyfilla, and indeed this is the most common brand, with a variety of products aimed at trade customers. They are used to fill in small holes and cracks. A product like Polycell Polyfilla Exterior Trade Filler can be used on the outside of buildings.

A search for ‘filler’ on the same web-site yields a wider variety of products including, unexpectedly, a great number of bath fillers. The first definition of ‘filler’ in the Oxford English Dictionary begins:

One who or that which fills

and in this case, it is not the material that fills the bath that is called the ‘filler’, but the device through which the water flows.

The other products are called ‘fillers’ in the sense given in the second OED definition, which begins:

Something used to fill a cavity, stop a gap, …

The first result is a calcium carbonate based ‘Joint Filler’, used to fill the joints between plasterboard. Then there are epoxy resin products to repair and fill gaps in metal and stone (such as this one), and wood fillers like this one, composed primarily of talc, calcium carbonate and styrene. There is a solid polypropylene ‘comb filler‘ to ‘fill’ the gap under profiled roof tiles, to prevent ingress by birds and vermin. There is a jointing filler for pointing pavements, that is for filling the gaps between the paving stones. Finally, among other products, there is a minimal-expanding polyurethane foam filler for filling ‘holes, gaps, cracks and cavities’ up to 25 mm in diameter:

and an expanding polyurethane based foam filler for ‘large, awkward or irregular gaps’.

Expanding polyurethane foam

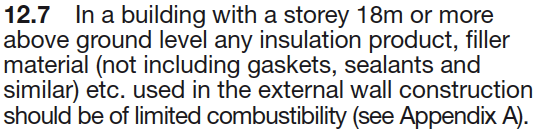

It is this last type of product, available in many brands, that is widely used on external facades. Foam is applied through a straw or with a gun:

expands to fill the gap:

and can be trimmed when dry with a knife or saw:

Three uses of polyurethane foam on high rise external walls

Three uses of PU foam on high rise external walls are commonly identified:

i) to fill gaps between rigid insulation boards;

ii) to fill gaps around penetrations;

iii) to fill gaps around windows.

The following two photographs from the Guardian may illustrate the first two types of gaps. The first is of Salix Court in Salford after ACM cladding panels had been removed last summer.

The dark strips down the middle of the wider vertical T-rails are not gaps but gaskets to create a seal with the panels. But a gap can be seen at the bottom left of the picture, between the insulation board and the L-rail:

It would appear that the gap continues the whole length of this board section, but has been covered with tape for most of its length. There is no indication that filler material has been used in this instance.

To the top right of the window, a hole has been cut in the insulation board, probably for the duct from a kitchen or bathroom extraction fan:

There is a large cavity around the duct, which again in this instance has not been filled with filler material.

Large unfilled cavities are visible at the bottom of the second photograph, which is of another tower block in Salford whose cladding has been removed:

and again there are sizeable unfilled gaps around the ducts next to the windows.

The following photograph may illustrate the type of gap there may be around a window unit:

On the exterior of this building of steel frame construction, the gap between the windows and the sheathing board were later spanned with an EPDM seal (black in the following photograph):

leaving a gap on the inside extending to the full depth of the wall:

In this particular job, the gap was filled with mineral wool, and sealed with a silicone sealant. A very common practice has been to fill it with expanding polyurethane foam.

Gaskets and sealants

Gaskets and sealants are used extensively on facades to prevent the passage of water and air. Some sealants may be designed to prevent the ingress of water, but allow water vapour to escape. These products are normally excluded from the limited combustibility requirement of 12.7:

As mentioned earlier, gaskets may be seen in the photographs above on the aluminium T-rails which held the ACM panels in place, before they were stripped off. The vertical black strips are the gaskets:

The vertical joints between the panels coincide with these gaskets. The panels are attached to the flange of the T-shaped rail, one on one side of the gasket, and one on the other, as shown in the following schematic drawing, which has the outer panels cut away to reveal the gasket and T-rail behind them:

The gasket prevents the panels rattling against the rail, and visually provides a black background instead of a shiny aluminium one. This particular model is made of PVC foam, which is of course combustible.

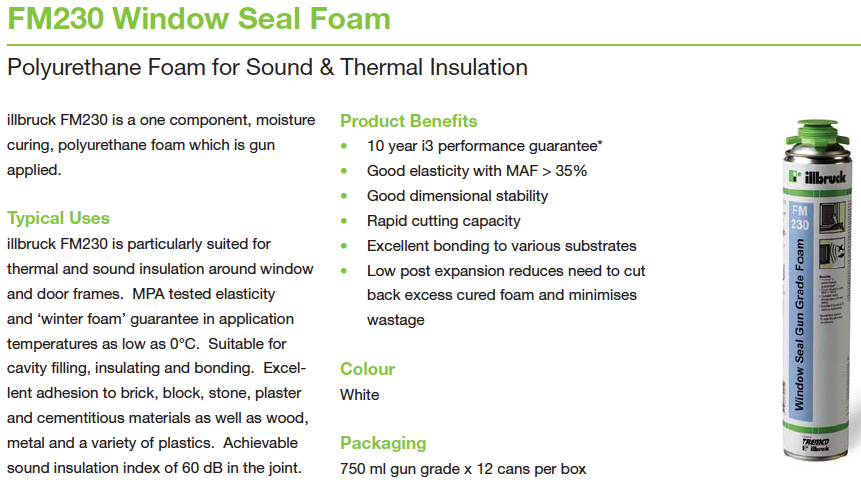

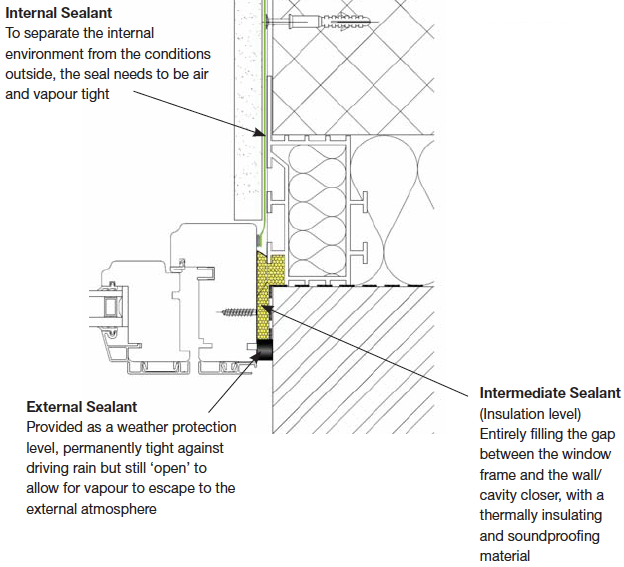

Items of this sort whose function is to create a seal are generally of low weight and so contribute little combustible material to a fire. It is possible however for a material to function as both filler and sealant. Tremco, for example, advertise (p. 20) a polyurethane foam product as an ‘Intermediate Sealant’ to fill the gap around windows:

The accompanying horizontal section (p. 7) shows the foam (in orange) ‘entirely filling’ the gap around the window:

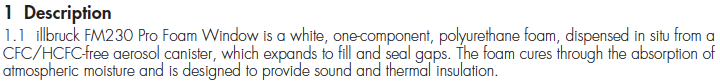

The product is described in its BBA Certificate as expanding ‘to fill and seal gaps’, and as providing thermal and sound insulation:

I do not think there is any difference in type between this PU foam product, advertised as a sealant, and the PU foam products advertised as fillers by other manufacturers. It cannot be, I think, that it is excluded from the limited combustibility requirement of 12.7 on the grounds that the manufacturer calls it a sealant, or that it serves some sealant function. It may be noted in this instance that it is used in conjunction with both an ‘External Sealant’ and an ‘Internal Sealant’, suggesting that its own sealant properties are limited. But it would seem in any case to belie the purpose of the clause to allow a combustible filler material to be used above 18 metres merely because it provided a seal as well filling a gap or cavity. What matters I think is the amount of combustible material present it adds to the construction.

Conclusion

Filler materials are used in external wall construction to fill gaps and cavities. Three applications that are often cited are the gaps around penetrations, around windows, and between rigid insulation boards. Polyurethane foam is widely used for this purpose. For buildings above 18 metres, these gaps may be filled instead with mineral wool and sealed with a sealant.

I believe this is how the term ‘filler material’ has been generally understood in the construction industry since its addition to the limited combustibility requirement for insulation materials and products employed in external wall construction.

Andrew Chapman

Notes:

- The wording of the limited combustibility requirement in the Northern Ireland guidance is different, with no mention of filler material, and no et cetera. Post-Grenfell guidance on the ‘Cladding or Re-Cladding of Buildings’ issued in September by the Northern Ireland Department of Finance makes no reference to a limited combustibility requirement for ACM cladding panels. ↩