I have been examining three alternative rationales offered by the DCLG for their claim that the core of ACM panels is covered by paragraph 12.7 of Approved Document B2:

1. The ACM core is an insulation material or product;

2. The ACM core is a filler material;

3. All elements of the cladding system are covered, and so the ACM core is covered.

As I explained in part 1 of this series, the first of these rationales may be excluded immediately because ACM cladding has no insulation function. I showed in part 2 that common sense, logic and informed opinion rule out the third rationale, the application of 12.7 being clearly restricted to insulation and filler materials, with any further coverage limited to minor unspecified items.

In this post I demonstrate that that the core of cladding panels made of Aluminium Composite Material cannot properly be described as filler material. As I pointed out before, the DCLG itself finds this a doubtful proposition since in footnote 4 of its Explanatory Note on safety checks and testing of 30 June 2017:

with its ‘and/or’, the core is claimed to be either an insulation material/product, or an filler material, or both (but not neither!) So, according to the logic of this footnote at least, the ACM core could be just an insulation product and not a filler material at all.

C) Is the ACM core a ‘filler material’?

I have so far found no evidence that the ACM core was ever described as a ‘filler’ or ‘filler material’ prior to 14 June 2017, the night of the Grenfell fire. Words acquire meaning through usage. What concerns us is the meaning of the term ‘filler material’ in Approved Document B2 12.7 at the time that the Grenfell Tower renovation was being planned by architects and others, assessed by building control, and undertaken by contractors. If the ACM core had never been referred to as a filler or filler material, how could anybody at that time possibly have understood that it fell under the limited combustibility requirement for filler material?

Despite this obvious objection to the idea, the DCLG has in fact been placing a great deal of weight on this rationale for claiming that the ACM core is covered by 12.7. From 22 June, they gradually replaced the normal term ‘core’ by the new term ‘filler’, until the latter became their standard usage. Shockingly, the BRE, which is I think still considered a reputable scientific and engineering research establishment, has aided and abetted the Government in this nefarious project to twist the meaning of words, by sometimes referring to the ACM core as ‘filler’ in its publicly available test reports on the BS 8414 large-scale tests it carried out on cladding systems for the DCLG, while continuing to use the normal scientific and professional term in its confidential test reports for commercial clients. What a disgrace.

C.1) The use of the term ‘filler’ for the ACM core by the DCLG and the BRE

C.1.1) DCLG letters concerning Safety checks, 18 June and 20 June

It would appear that four days after the Grenfell Tower fire, the normal term ‘core’ still retained its currency in the DCLG. In the Annex to a letter dated 18 June from Melanie Dawes, Permanent Secretary at the DCLG, to the Chief Executives of Local Authorities and Housing Associations, ACM panels are described as consisting of

two thin aluminium sheets bonded to a non-aluminium core

The ‘core material’, she said, should be of limited combustibility:

and the ‘core materials’ needed to be tested, she said, to identify what type they were:

The ACM core is never referred to as a filler or filler material in this letter.

Another letter sent two days later to owners, landlords and managers of private residential blocks on the 20 June contains the same three references to the ACM core or core material. Again, there is no mention of a filler or filler material.

C.1.2) Further DCLG letter on Safety Checks, 22 June 2017

On 22 June came the first explanation for the claim made on 18 June that the Approved Document guidance required the ACM core to be of limited combustibility. The Annex to a further letter written by Melanie Dawes to the Local Authority and Housing Association Chief Executives on that date contained the following footnote (identical to footnote 4 of the Explanatory Note of 30 June, shown above):

and reproduced with the terms ‘core’, ‘filler’ and ‘filler material’ highlighted:

For the avoidance of doubt; the core (filler) within an Aluminium Composite Material (ACM) is an “insulation material/product”, “insulation product”, and/or “filler material” as referred to in Paragraph 12.7 (“Insulation Materials/Products”) in Section 12 “Construction of external walls” of Approved Document B (Fire safety) Volume 2 Buildings other than dwelling houses. (The important point to note is that Paragraph 12.7 does not just apply to thermal insulation within the wall construction, but applies to any element of the cladding system, including, therefore, the core of the ACM).

It is rather as if, as the footnote progresses, the DCLG loses confidence in its contention that the core is a filler material:

i) The parenthetical addition of ‘filler’ to ‘core’ implies that the ACM core is a filler.

ii) It is nevertheless doubtful, because of the ‘and/or’, whether this ‘core (filler)’ is in fact a ‘filler material’.

iii) Finally, the ACM core is referred to simply as the core.

C.1.3) DCLG Explanatory Note on safety checks and testing, 30 June 2017

In the Explanatory Note of 30 June, the two terms ‘filler’ and ‘core’ are generally employed in conjunction with each other. It seems to me that the DCLG wants to use the term ‘filler’ for the core, so that ACM panels will be subject to the limited combustibility requirement for filler material in 12.7, but is aware that the term will not be understood if used on its own.

In paragraph 12, we find ‘core or filler’:

and similarly, ‘core or filler material’ in the following paragraph:

Again, in paragraph 20, ‘filler’ is followed epexegetically by ‘core of the panel’:

And in paragraph 3 of Annex A, we find ‘the filler material in the core of the panel’, with ‘core’ apparently signifying place rather than substance:

By paragraph 7 of the Annex, the authors appear to have judged their readers ready to comprehend the meaning of ‘filler’ on its own:

and ‘filler material’ stands on its own in the Summary, which perhaps was written last:

At the same time, in the Explanatory Note, the DCLG several times refers to the ACM core as what it is, the core, as for example in paragraph 20:

and in paragraphs 2, 4 and 6 of the Annex. Similarly the DCLG refer to the material the core is made of as the ‘core material’ rather than ‘filler material’, as for example in paragraph 12:

and in paragraphs 2, 5 and 6 of the Annex.

C.1.4) DCLG Explanatory note on large scale cladding systems testing, 20 July 2017

Three weeks later, in their Explanatory note on large-scale … testing of 20 July, the DCLG were using the term ‘filler’ almost exclusively, the word occurring sixteen times in the document, while ‘core’ is used just once and in conjunction with the new term (paragraph 4):

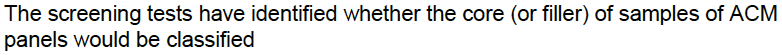

Elsewhere in the document, ‘filler’ is used to denote the core, as for example in this table in paragraph 14:

C.1.5) BRE Global Client Report, DCLG Test 1, 27 July 2017

Between 23 July and 8 August 2017, the BRE conducted seven large-scale BS 8414 tests of cladding systems on behalf of the DCLG. The first issue of its report on the first of these, a system incorporating PE ACM panels and PIR insulation, was published on 28 July.

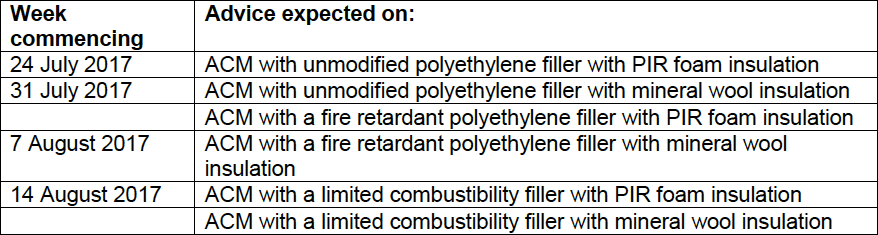

The first use in the report of both words ‘core’ and ‘filler’ is in the designation of the core material as the ‘core filler material’:

In 4.3 we have PE ‘filler’:

In 7.1.1 we find first ‘core material’:

and then ‘”filler” material’, with inverted commas in the original:

Is it normal to place quotation marks around a term in a technical report? Why are they there? Is it to stand for ‘so-called’, as in ‘there was no … so-called filler material’? Does it not betray a certain awkwardness on the part of the author?

Then in Appendix B, we have ‘core or filler’:

Again, is this not very odd in a technical report? Is it not normal to have one term for one item, and to use it consistently?

C.1.6) BRE Global confidential Classification Report, August 2017

I have seen a confidential report by BRE Global for a leading ACM panel manufacturer of a BS 8414 test of a cladding system incorporating the FR (fire retardant version) grade of their product. As a Classification Report, it is much shorter than a Test Report, and lacks much of the detailed information contained in the latter. Nevertheless, its Section 2, ‘Details of the Classified Product’, is roughly comparable to Section 4, ‘Description of the system’ in the Report for DCLG Test 1 described above.

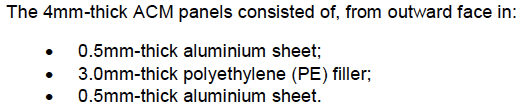

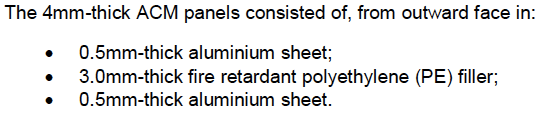

The panels are described as follows. I have redacted the name of the product, and the description of the core (since the same description is used by the manufacturer in publicly available documents):

The ... panels were 4mm-thick in total, formed from 0.5mm-thick aluminium skins either side of a ... core.

The word ‘filler’ does not appear in the Report at all. I showed above the description of the PE ACM panels in DCLG Test 1 Report, Issue 1.0, dated 27 July 2017. Here is the similar description of the FR ACM panels in the DCLG Test 3 Report, Issue 1.1, dated 8 August 2017:

Issue 1.2, dated 12 September 2017, has the identical description. The BRE calls the core the ‘filler’ in these publically available reports both before and after the classified report, in which it uses the universally acceptable term. In classified reports it uses the proper term, the ‘core’. What a disgrace. I grew up believing that the BRE was a serious and reputable scientific and engineering research body. Has it now become a propaganda arm of the Government?

C.2) ‘Core’ is the normal term

C.2.1) Manufacturers’ descriptions

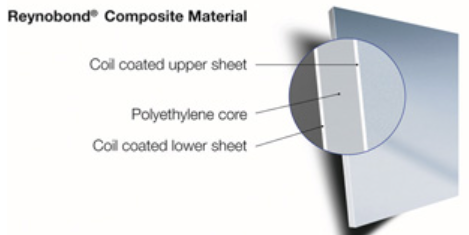

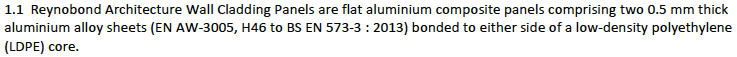

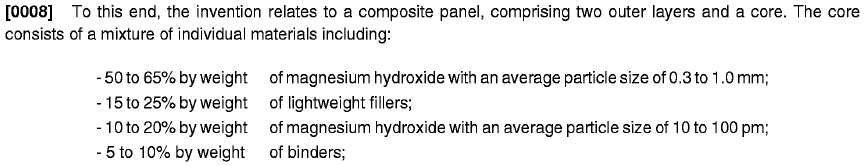

The following manufacturers’ diagrams may serve the dual purpose of explaining the structure of ACM cladding panels, and beginning to demonstrate the consistency with which the middle layer of the product is called the core. The product used at Grenfell Tower, Reynobond PE, is represented by its manufacturer Arconic with the following simple diagram:

The panels consist of two aluminium sheets, only 0.5 mm thick, chemically bonded (2.2.A) to an extruded polyethylene core, 3 to 6 mm thick.

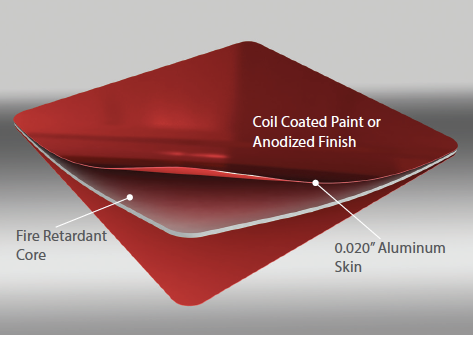

Alucobond Plus, a fire retardant product from 3a Composites, is represented as follows for the American market (0.020″ being about 0.5 mm):

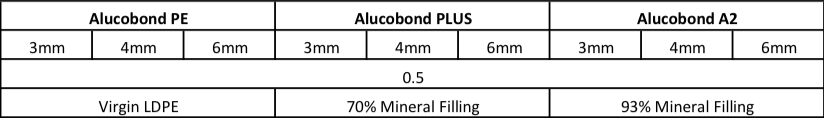

This fire retardant core is composed of polyethylene with 70% mineral filling (whether by weight or volume is not specified), as shown by the Alucobond Technical Data Sheet:

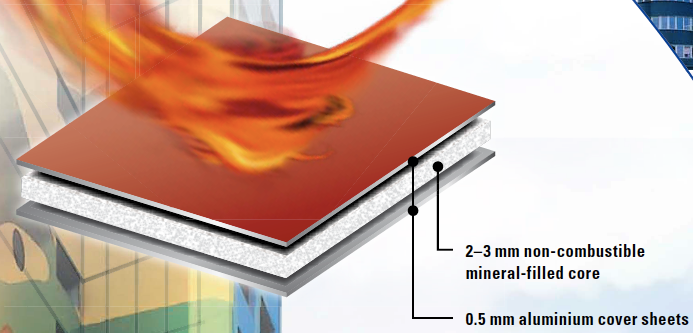

The A2 product has 93% mineral content, and is pictured as highly fire resistant, this time for the European market. The core is described as a ‘mineral-filled core’:

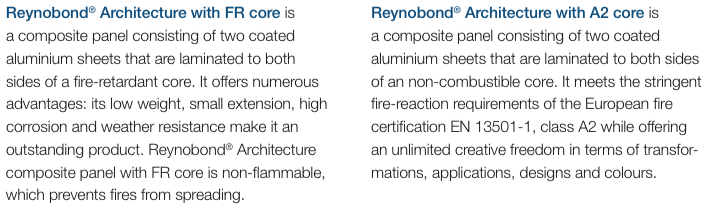

Similarly, Arconic describe the core of their Reynobond FR and A2 products as ‘fire-retardant core’ and ‘non-combustible core’ respectively:

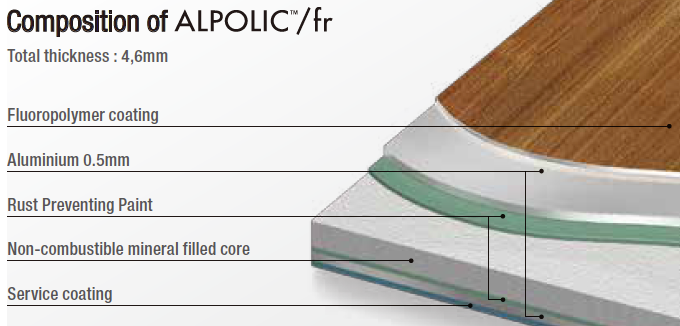

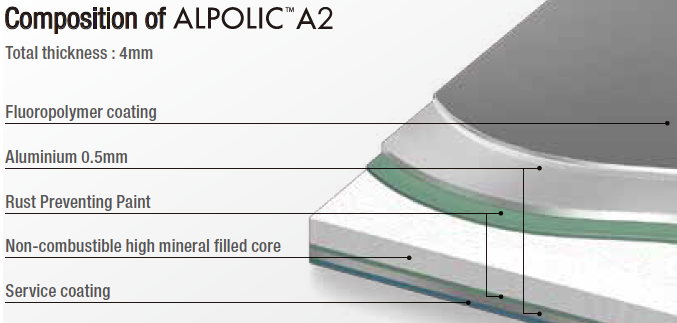

Mitsubishi describe the core of their FR and A2 products as ‘mineral filled core’ and ‘high mineral filled core’ respectively:

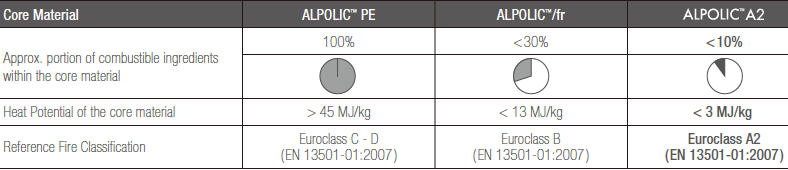

In passing, the manufacturer’s description of the Alpolic FR core as ‘non-combustible’ is misleading. Its calorific value is given as something less than 13 MJ/kg, more than four times the value considered to be of ‘limited combustibility’ in the UK:

C.2.2) Certificates and classification reports for ACM panels

According to a recent (August 2017) BBA Agrément Certificate, Reynobond ACM panels comprise two aluminium sheets bonded to either side of a PE core:

Similarly, a BBA Agrément Certificate with the same date describes Alucobond as consisting of a core layer bonded either side to aluminium outer skins:

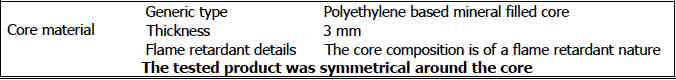

A Reaction to Fire Classification Report issued by Warrington Fire in 2010 to Mitsubishi described the ‘core material’ of Alpolic A2 ACM as ‘polyethylene based mineral filled core’:

The core has a mineral filling. The mineral is the filler. The core, which is polyethylene based, is not the filler. It is partially filled with mineral content.

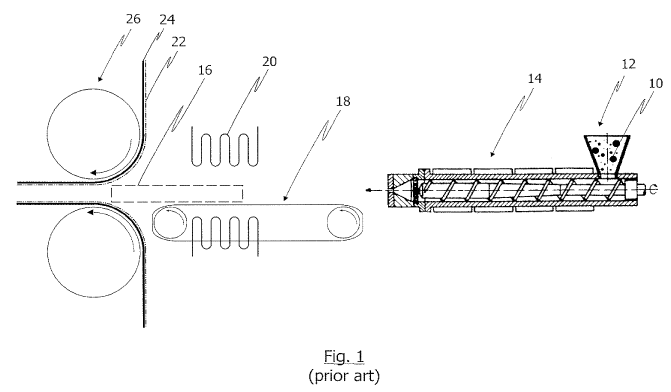

C.2.3) Patents for ACM panels

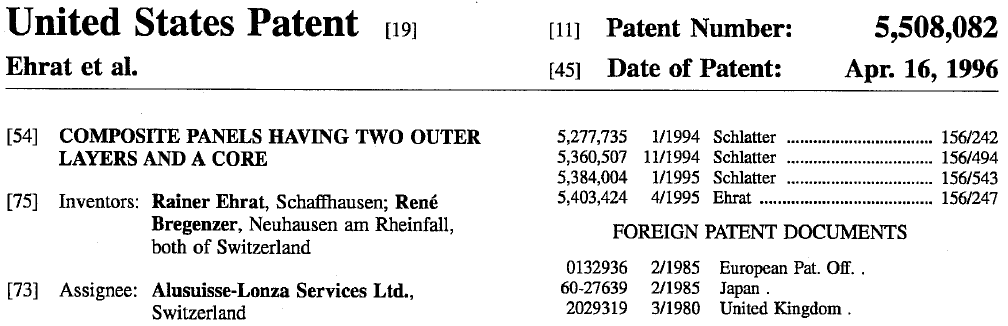

C.2.3a) Alusuisse, 1996

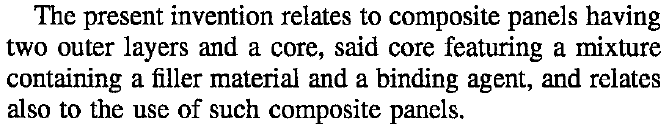

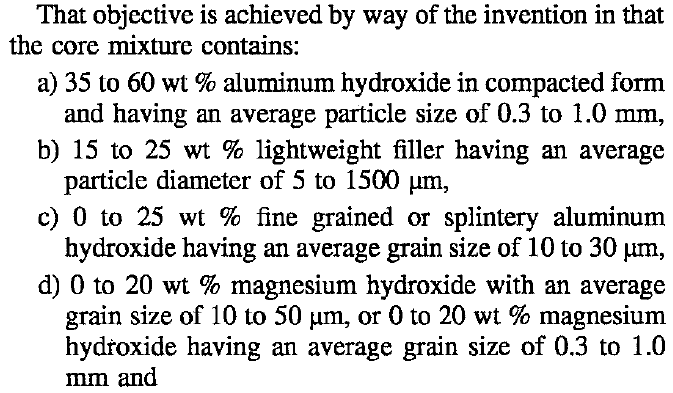

In 1996, a U.S. patent was awarded to the Swiss aluminium production company Alusuisse for aluminium composite panels having

two outer layers and a core

and a ‘high fire-proofing capacity’:

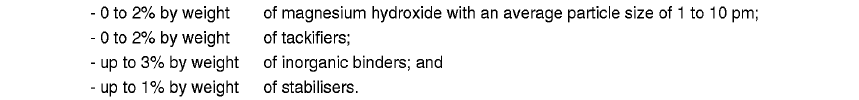

The core was described at its simplest as being comprised of a mixture of ‘filler material’ and binding agent:

In more detail, the filler material was 90-96% of the total by weight and consisted of aluminium hydroxide of two different grain size, magnesium hydroxide, and a ‘lightweight filler’:

Hollow glass spheres and foamed glass are later specified as specially preferred lightweight filler materials. The binding agent was 4 to 10% of the total by weight, polymer-based, and subject to elasticity and elongation requirements:

The most useful binding agents are those consisting largely of polyethylene:

Thus, the polyethylene or other polymer component of the core is not described as filler material, but as binding agent; the mineral component of the core is the filler material. The core is not the filler.

C.2.3b) Alcoa, 2010

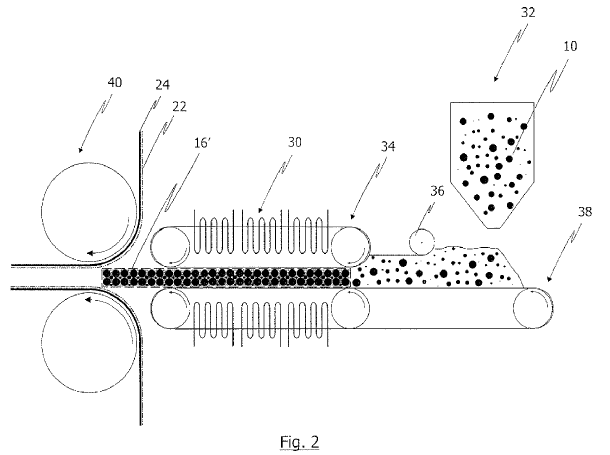

In 2010, Alcoa, as the manufacturer of Reynobond ACM panels (now Arconic) was then called, applied for a patent for a ‘non-combustible’ ACM panel, and manufacturing method to go with it. One object of ‘the present invention’ was to reduce the calorific value (heat of combustion) of the core material to below 2.5 MJ/kg and thus achieve the French M0 Class as well as Euro Class A2. Again, the panels comprised:

two outer layers and a core

A diagram shows the proposed manufacturing method. The core materials are first pressed together to form a solid sheet, which is then pressed together with the outer layers by laminating rolls to form the composite material:

Under the existing method, shown in another figure, the core sheet is formed by extrusion rather than with a press, but is joined to the outer layers in the same way with laminating rolls:

With both methods, the composite panel is formed from three solid layers. I do not think it would be natural here to speak of the two outer layers being ‘filled’ with the central layer. If anything, one might prefer to say that the central layer was faced with the outer layers. But in practice, I think this would normally be described as a laminating process.

Again, the core consists of a number of materials, with ‘lightweight fillers’ among the mineral fillers:

The core is not the filler.

C.2.4) A textbook

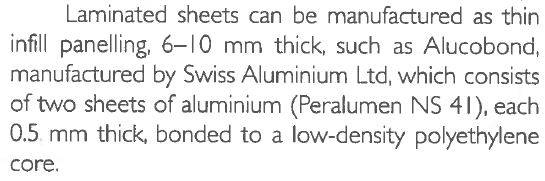

In the fourth edition of Cladding of Buildings by Brookes and Meijs (2008), Alucobond ACM panels (once manufactured by Swiss Aluminium Ltd) are described as consisting of two 0.5 mm aluminium sheets bonded to a ‘polyethylene core’:

C.3) Mineral fillers

The Encyclopedia of Polymer Science and Technology describes fillers as:

particulate materials added to polymers in order to improve the physical properties and/or to reduce the cost of the composite.

Examples of fillers are carbon black, calcium carbonate, talc and silica. They are added to polymers to increase their stiffness and their fire resistance (p. 123):

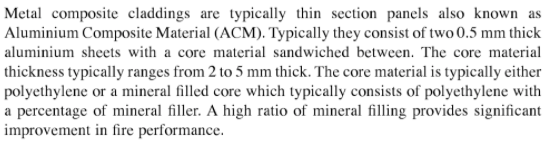

Professor Michael Delichatsios, then Director of the Institute for Fire Safety Engineering Research and Technology (FireSERT) at the University of Ulster, with his co-author Nathan White, in their study of Fire Hazards of Exterior Wall Assemblies Containing Combustible Components (Springer, 2015) described the use of such mineral fillers in ACM cladding panels:

The core material is typically either polyethylene or a mineral filled core which typically consists of polyethylene with a percentage of mineral filler.

It can be seen that confusion would likely result from terming the ACM core the filler, since then the filler would contain a certain percentage of filler.

C.3.1) BRE descriptions of cores with mineral fillers

In the BRE Reports on the DCLG tests the ‘core filler’ of FR ACM panels is described as ‘fire retardant polyethylene’, while for A2 panels the description is ‘limited combustibility mineral’:

In the BRE Reports on DCLG tests 5 and 6 on systems with A2 ACM panels, the ACM core is described as being itself a ‘mineral filler’:

These are misleading descriptions. We have seen that mineral fillers are added to a polymer base – the polymer is bulked out with the mineral. If the mineral content is very high, then it becomes possible to speak of the core as constituted of mineral with polymer binder, rather than polymer with high percentage of mineral filler. Either is acceptable.

It is odd to describe the core simply as ‘mineral’. It’s even stranger to describe it as ‘mineral filler’. What is the mineral meant to be filling, the aluminium facings?! No, this is a mineral filled core, not a ‘mineral filler’.

C.4) Is filler or filler material a natural term for the central layer of an ACM panel?

C.4.1) Does the core fill the panel?

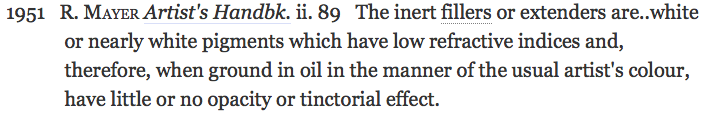

Fillers fill. The first definition of ‘filler’ in the Oxford English Dictionary begins:

One who or that which fills

We may perhaps distinguish between malleable, fluid or solid particulate fillers that are used to fill a void in something solid; and solid fillers, such as the mineral fillers discussed above, which are added to something fluid. Both types may be seen in the second main definition of ‘filler’ given in the OED:

Polyfilla may serve as a homely example of a malleable substance used to fill cavities in solid materials.

The ACM core is not a filler of either of these types. It is not as if it is poured between the aluminium sheets before solidifying. The three solid layers are laminated together.

C.4.2) Is the core non-essential to the structure of the panel?

Most often, I think, the thing to which a filler is added can perform its central function in the absence of the filler. The wall can stand without Polyfilla filling in the holes, and without cavity fill insulation in its cavity. The ‘filler’ in a TV schedule or music album is subsidiary to the main content. The artist’s oil paint fillers have little effect on the colour of the paint:

In contrast, the 3-6 mm ACM core plays I think a more or less equal part with the 0.5 mm facings in providing strength, rigidity and resilience to the panels. ACM is a true composite. The core is not just filling in space or providing bulk.

C.4.3) A counter example

These general considerations about the meaning of the word ‘filler’ do not however in themselves prove that it is not a proper term for the ACM core. A ham sandwich may demonstrate the point. All three main layers are solid, and the ham surely is essential to the central purpose of the whole. It is nevertheless classed as a sandwich filler.

The meaning of a word can branch off in new and surprising directions. A different type of composite panel, typically with steel facings and insulating core, is commonly known as a sandwich panel. The notion of two similar outer layers and a different inner layer seems to be transferable from one domain to another. I do not think it would be wholly unnatural for the inner layer of a composite panel to be called its filler. One could view it as filling the gap in the middle, so to say. The main question is whether such usage develops or not.

C.4.4) The development of a new meaning

After all, the Government would hardly have been able to put forward ‘filler’ and ‘filler material’ as terms for the core and core material unless they were a tolerable fit. Even so, it has been remarkable to see the rapidity with which the term has been disseminated from the organs of the state into common parlance.

To take one example, the Government published on 2 August 2017 a ‘News story’ about the second of its large-scale cladding tests at the BRE. A system with mineral wool insulation and ACM panels with a ‘polyethylene filler’ failed the test:

In their reports of the story, the term for the ACM core used by the Government was employed also by the BBC:

by ITV:

and by the Guardian:

The vast majority of readers would I think never even have heard of ACM cladding panels and would have no reason to reject the term used for the core. They would simply adopt ‘filler’ as the word they would use for it. Thus can a new meaning for a word be born. It is a fearful thing to see our national Government manipulating language to preserve its position and power.

C.5) Searches for ‘core’ and ‘filler’

I have been referring to ‘filler’ as a new term for the ACM core, invented by the Government subsequent to the Grenfell fire. Can a single example be found of the word being used in this way prior to 14 June 2017?

C.5.1) 1st search

I conducted a simple search in a university library catalogue for items of any type containing the following terms:

aluminium + composite + panel + cladding + polyethylene + core

I then repeated the search with ‘core’ replaced by ‘filler’:

aluminium + composite + panel + cladding + polyethylene + filler

C.5.1a) 1st run with ‘core’

The first run, with ‘core’, yielded the following four relevant papers from a total of thirty results, with the test for relevance being that they concerned ACM panels:

1) Nishio, Y., Yoshioka, H., Noguchi, T., Kanematsu, M., Ando, T., Hase, Y., & Hayakawa, T. (2016). Fire Spread Caused by Combustible Facades in Japan. Fire Technology, 52(4), 1081-1106.

ACM panels are described as ‘aluminium sheets … sandwiching the core material’:

2) Verzoni, Angelo. London Calling. NFPA Journal Volume: 111 Issue 5 (2017) ISSN: 1054-8793 (online version of article)

The NFPA Journal is the magazine of the United States based National Fire Protection Association. ACM panels are described as ‘thin aluminium panels [sic] sandwiching a plastic core’:

3) Dimoudi, A; Tompa, C. ‘Energy and environmental indicators related to construction of office buildings’. Resources, Conservation and Recycling Volume: 53 Issue 1-2 (2008) pp. 86-95.

The ACM panels are described as consisting of ‘two aluminium sheets … with a polyethylene core’:

4) Aparicio-Fernández, Carolina ; Vivancos, José-Luis ; Ferrer-Gisbert, Pablo ; Royo-Pastor, Rafael. ‘Energy performance of a ventilated façade by simulation with experimental validation’. Applied Thermal Engineering, May 2014, Vol.66(1-2), pp.563-570.

The ACM panels are described as consisting of ‘two aluminium sheets bonded to an aluminium core’. (The reference to them as ‘sandwich panels’ may perhaps reflect Spanish terminology.)

The core is described as ‘mineral-filled’. The core does not fill the panel. Mineral fillers are added to the core. The core is not the filler:

C.5.1b) 2nd run with ‘filler’

The second run, with ‘filler’, yielded no relevant papers from a total of fifteen results.

C.5.2) 2nd search

I conducted another simple search, with the same terms, in another university library catalogue. The first run, with ‘core’, yielded the following five further articles and papers on ACM panels from the first fifty of a total of 251 results. I have omitted the Nishio paper found in the first search.

C.5.2a) 1st run with ‘core’

5) DuPont, Alcoa collaborate on hurricane-resistant panel. (2006). Concrete Products, 109(7), 32.

A new product featured a layer of Kevlar fabric between Reynobond aluminium skins and ‘polyethylene core’:

6) Sullivan, C., & Horwitz-Bennett, B. (2009). Novel Materials, Tried and True. Building Design & Construction,50(3), 43-47.

The chairman of the Metal Composite Material Fabricators Council in the United States explained that ACMs were composed of aluminium sheets over a ‘polyethylene core’:

7) Webb, S. (2015). Sign Assembly: Adhesive. Sign Builder Illustrated, 29(237), 58-60.

An article in Sign Builder Illustrated described ACM as being comprised of aluminium sheets and ‘a core of either polypropylene or polyethylene’:

8) Gandhi, Jagdish, Karthikeyan, Chakravarthy, Nakrani, Ghoroi, & Srivastava. (2017). Performance of glass-ACP façade system in a full-scale real fire test in a G+2 structure. Procedia Engineering, 210, 512-519.

In a paper presented in China in December 2017 on a full-scale fire test conducted in India by an Indian Institute of Technology in Gujarat in collaboration with Underwriters Laboratories, the aluminium composite panels were described as being composed of ‘a polyethylene core laminated and sandwiched’ between two aluminium sheets:

9) Hsu, Wang, & Tzeng. (2012). The best vendor selection for conducting the recycled material based on a hybrid MCDM model combining DANP with VIKOR. Resources, Conservation & Recycling,66, 95-111.

In a paper on the use of recycled materials in the production of ACM panels in Taiwan, the product is described as being produced by laminating aluminium with a ‘fire resistant mineral-filled or polyethylene core’:

C.5.2b) 2nd run with ‘filler’

The second run, with ‘filler’ instead of ‘core’, yielded no relevant articles or papers from the first fifty of a total of 103 results.

A Challenge

I challenge the Government of the United Kingdom to produce a single instance of the terms ‘filler’ or ‘filler material’ being used for the ACM core in a publicly available form prior to 14 June 2017. If you, the elected Government, are unable to do so, then you have no right to say that combustible ACM panels installed before that terrible day were non-compliant with paragraph 12.7 of your Approved Document B2 Fire Safety guidance, on the grounds that their core was a filler material.

Andrew Chapman

(Next: What is a filler material?)