[continued from part 2]

bba certificate 08/4582 (2008) for kooltherm K15

In October 2008, the BBA issued Agrément 08/4582 (Product Sheet 1) for Kingspan’s Kooltherm K15, a phenolic insulation board designed for rainscreen applications:

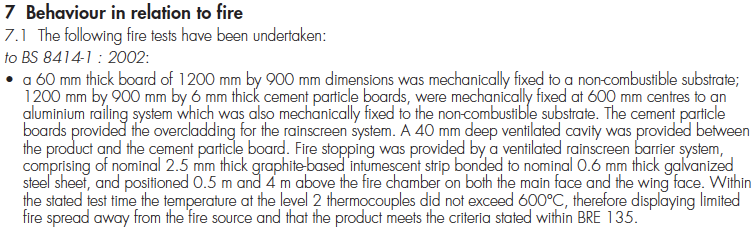

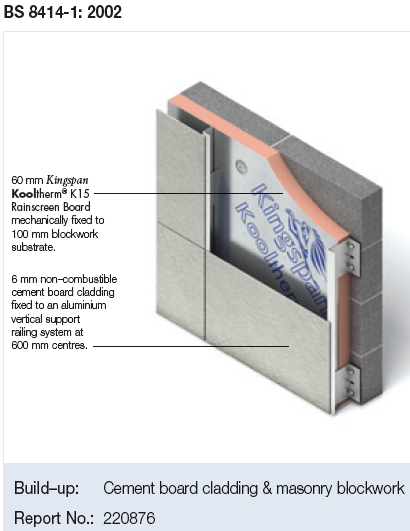

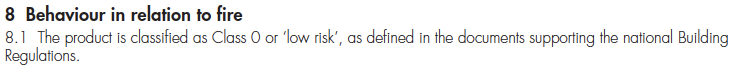

Section 7 of the Certificate concerns ‘Behaviour in relation to fire’. Only two fire tests are recorded as having been undertaken. The second of these, to BS EN 1364-1, is for the fire resistance of non-load bearing walls (the ability to prevent the spread of fire from one side of a wall to the other), and is not relevant to the requirements of AD B2 12.5 to 12.9. The first is a large-scale system test to BS 8414-1/BR 135:

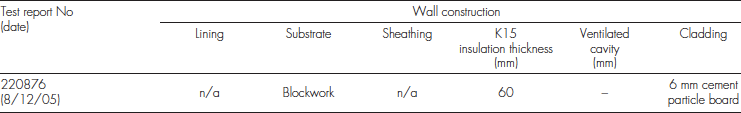

The outer cladding was provided by cement particle boards, and the system is reported as having passed the test according to the criteria of BRE 135. A later Certificate (BBA 14/5134 Sheet 7, 2015) indicates that the test had been carried out in December 2005, with report number 220876:

[ADDED 1 MARCH 2018

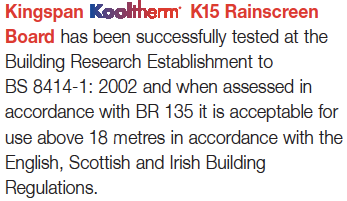

An advert for Kooltherm K15 in the August 2016 edition of International Fire Protection magazine, misleadingly claimed that the product had been ‘successfully tested’ to BS 8414-1:2002, and that when assessed in accordance with BR 135, it was

acceptable for use above 18 metres

in accordance with the Building Regulations:

But nothing could be ‘successfully tested’ to BS 8414-1:2002, since it contains no criteria for success or failure. Moreover, BS 8414-1:2002 is the British Standard for a test method for cladding systems, not for individual products:

I think it is highly misleading to claim that the product has been tested to this standard without even mentioning the system of which it was a part. It was the system that was tested to BS 8414-1:2005, not the insulation component per se.

Worse still, the claim that the product can be used above 18 metres ‘in accordance with’ the Building Regulations, is ambiguous. Does it mean:

i) it can be used above 18 metres, as the Building Regulations indicate; or

ii) it can be used above 18 metres, if used in a way that is in accordance with the Building Regulations?

It seems very probably that many will have read it the first way. If Kingspan were not trying to mislead, why did they not simply state that the product could be used above 18 metres as part of the system that was tested?

END OF ADDED SECTION.]

Class 0 (England and Wales) and ‘low risk’ (Scotland)

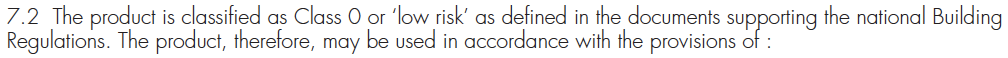

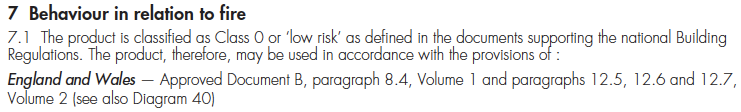

There is no record of testing to BS 476 parts 7 and 6, and yet in the next sub-section (7.2) it is stated that the product is Class 0 [England and Wales] or ‘low risk’ [Scotland] as defined in the national Building Regulations:

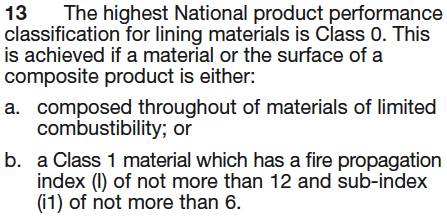

There are two ways of achieving Class 0 (AD B2 Appendix A.13):

Read literally, it would appear that a composite product can achieve Class 0 if its ‘surface’ is composed ‘throughout’ of materials of limited combustibility. It seems a little odd to speak of a surface being composed ‘throughout’ of something, but perhaps this is conceivable. The facings of Kooltherm K15 are a composite foil, but it may be that the surface itself is aluminium, which is classified as non-combustible. 1 Is it possible that the product has been given a Class 0 rating without a fire test on this basis?

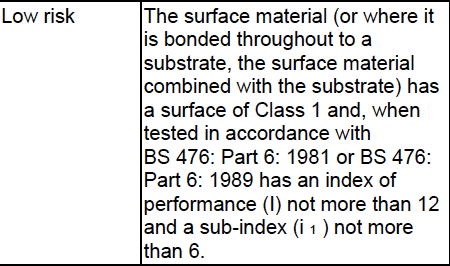

Such an explanation is not possible for the classification of the product as ‘low risk’ under the Scottish building regulations. The 2007 Technical Handbook (Domestic) defines ‘low risk’ under the national class as follows:

There is no way to achieve the ‘low risk’ classification without a fire test to BS 476 part 7 to achieve Class 1, followed by a test to BS 476 part 6. So it would appear, assuming that the Certificate is accurate, that both tests were in fact taken and the required results achieved.

The test results required are exactly the same as those for Class 0 (England & Wales). Class 0 (England & Wales) would then also have been achieved through the route described in 13.b, so that there would then be no need for the alternative explanation of the rating being achieve through a rather doubtful interpretation of 13.a, with no fire tests.

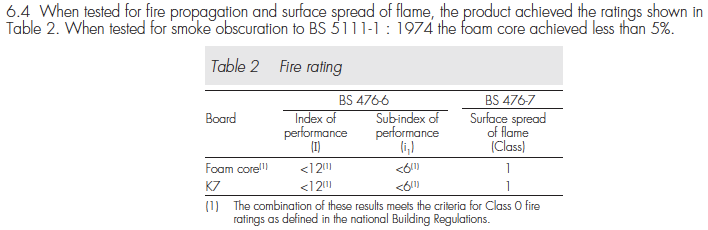

But if the BS 476 tests were taken, it is strange that there is no record of them in the Certificate. By way of contrast, in BBA Certificate 94/3061 for Kingspan Kooltherm K7, it is definitely stated that the product was tested to BS 476 parts 7 and 6:

So I remain perplexed as to why the BBA specifies Class 0 and ‘low risk’ ratings for Kooltherm K15 without any indication of the product have undergone the relevant BS 476 tests.

Use according to Diagram 40

The Kooltherm K15 Certificate 08/84582 (2008) goes on to say that because it is Class 0, the product may therefore be used according to the provisions of AD B2 12.5 and 12.6, with Diagram 40:

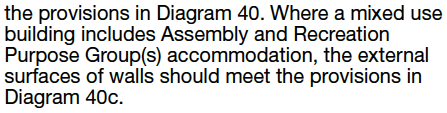

The then current 2006 edition (amended 2007) of AD B2 read as it does now at 12.6:

The highest rating required in Diagram 40 is Class 0, with Euro Class B as an alternative. So Kooltherm K15 could in principle be used for an external surface if all other building regulation requirements were met.

But from a practical point of view such insulation boards would never be used as the external surface. It is a rain screen product to be employed with an outer cladding and, apart from anything else, has the manufacturer’s name and logo all over it: 2

So I am puzzled as to why the BBA Certificate states that the product may be used ‘in accordance with the provisions of … 12.6’, if it never would be so used.

use over 18 metres

The next section (7.3) of the Certificate stipulated that for buildings with a floor above 18 metres:

advice should be sought from the Certificate holder.

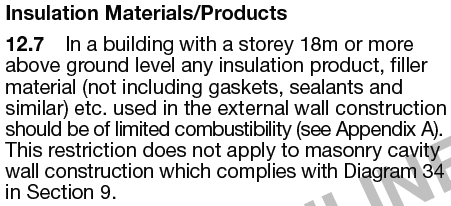

Being combustible, and an insulation product, Kooltherm K15 could not satisfy the requirements of AD B2 12.7, which read then as it does now:

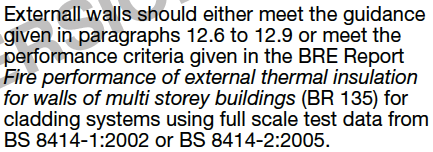

The only way it could be used in compliance with the Approved Document, therefore, was as part of a cladding system that had been found to satisfy the BR 135 criteria using full scale test data from BS 8414 (12.5):

In December 2008, when this certificate was issued, there had been just one test to BS 8414 of a system which included Kooltherm K15. It is described in section 7.1 of the Certificate, as shown above. The Test Report Number, 220876, allows this cladding system to be identified with one shown in Kingspan’s Technical Bulletin ‘Routes to Compliance‘ (First Issue, August 2015):

Key features and elements, apart from the 60 mm insulation boards, are the cement particle cladding boards, the 40 mm deep cavity between the insulation boards and the cement particle boards, the graphite-based intumescent cavity barriers, and the aluminium railing system. Clearly, the fire behaviour of the system will depend on all its features and elements, and not just on the insulation boards. The 2013 edition of BR 135 states explicitly that a classification to BS 8414/BR 135 applies only to the specific system tested (A2, p. 19):

and I think this principle would have been self-evident already in 2008.

I would have expected therefore that BBA Certificate 08/4582 (2008) would have stated simply that Kooltherm K15 could only be used above 18 m as part of the system detailed in test report 220876. To use it as part of some other system would require a test to BS 8414/BR 135 and probably an amendment to the BBA Certificate to include the new approved system.

Instead, the user of the product is advised to contact the Certificate holder, which is Kingspan, its manufacturer. What advice did Kingspan give? Did they say that it had to be used as part of the system specified in test report 220876, and make all the relevant information available to the potential purchaser? Or did they sometimes advise that their product could be used as part of some other system, without testing it to BS 8414/BR 135?

I will come back to this question after considering the change in certification that occurred in 2013. First, however, we need to examine two important amendments to BBA 08/4582 that were made in 2010.

BBA 08/4582 (2008, amended 2010)

BBA 08/4582 was amended in April 2010, with revisions being made to Section 7 on ‘Behaviour in Relation to Fire’:

Kooltherm K15 is again classified as Class 0 (England and Wales) or ‘low risk’ (Scotland), without any reference being made to tests to BS 476 parts 7 and 6. But now it is claimed that, because it is Class 0, it is therefore useable in accordance with the provisions of 12.7 as well as those of 12.5 and 12.6:

It seems to me that this certification by the BBA was in breach of the building regulations. Paragraph 12.7 only applies to buildings with a storey 18m or more above ground level. It requires that insulation products be of ‘limited combustibility’ as defined in AD B2 Appendix A, and and it is undisputed that phenolic insulation boards are unable to achieve such a rating. So how could the BBA state that:

The product … may be used in accordance with the provisions of … Approved Document B … paragraph … 12.7, Volume 2 [?]

In my opinion, this is a question that the public enquiry would do well do investigate. Did a lawless culture develop in the façade industry, which smiled at such apparently flagrant transgressions of the regulations?

CWCT Technical Note 73, March 2011

The CWCT’s Technical Note 73 (now removed upon request from CWCT) on ‘Fire performance of curtain walls and rainscreens’, which I referred to in part 1 of this series, was issued in March 2011, just under a year after the revision of BBA 08/4582. Having stated that AD B2 requires insulation materials used in buildings of over 18 m to be of limited combustibility, TN 73 observes that:

The only commonly used insulation material that will satisfy the definition of limited combustibility is mineral wool.

The CWCT reported, however, that:

It is sometimes argued that thermoset insulation materials with non combustible facings may be regarded as satisfying the requirement

The three commonly used thermoset insulation materials, PUR, PIR and phenolic resin, do not satisfy the ‘limited combustibility’ requirement of AD B2 12.7, as defined in AD B2 Appendix A. To ‘regard’ them as so doing is to enter into a world of fantasy and make-believe. It is also to introduce a dangerous element of uncertainty and ambiguity into the interpretation of the building regulations, whose meaning had previously had been clear enough.

One possible explanation for the BBA’s assertion that Kooltherm K15 could be used in accordance with AD B2 12.7 is that the BBA, whose remit is to help supply the construction industry with products of the highest quality, was ‘regarding’ it as being as of limited combustibility, even though it actually is not, as defined in AD B2 Appendix A.

retraction of claim that BS 8414 test met BR 135 criteria

The original 2008 Certificate contained, as shown before near the top of this post, a description of the BS 8414 test, with the conclusion that the temperature at the level 2 thermocouples did not exceed 600° C:

These two claims of limited fire spread and satisfaction of the BRE 135 criteria are absent from the 2010 amended Certificate, while the rest of the description of the test remains the same:

The removal of the two claims plausibly indicates that they may have been found to be untrue or uncertain. The edition of BRE 135 then current was that of 2003. As in BRE 135:2013, the only criteria that have to be met to avoid a definite failure are that none of the two sets of Level 2 thermocouples exceed 600° C above ambient during the first 15 minutes of the test. BBA 08/4582 declares in effect (since ambient was no doubt above 0° C) that these criteria were met during the ‘stated test time’, but does not tell us what this test time was.

BRE 135:2013 identifies the 600° C temperature rise with the degree of fire spread. Taking ‘External fire spread’ as an example:

[ADDED 18 JANUARY 2018, AFTER VIEWING BR 135:2003. REPLACES SOME PREVIOUS MATERIAL.

The failure criteria were specified in the same way in the 2003 edition. Here, for example, is the External Fire Spread criterion (with apologies for the poor quality photograph taken in the British Library):

The 2010 amended certificate states that

within the stated test time

the temperature of the level 2 thermocouples did not exceed 600° C. If the ‘stated test time’ were 15 minutes or more, then the system would have met the BR 135 criteria. Why then did the 2010 amended certificate no longer state that fire spread was limited and that the BR 135 criteria had been met?

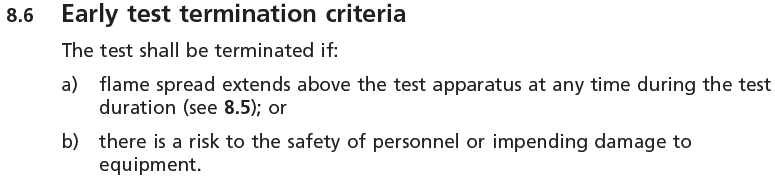

One logical possibility is that the test was terminated before 15 minutes had passed. In the later BS 8414-1:2015 edition, two criteria are given for terminating the test early:

In the previous edition, BS 8414-1:2002, which was in force at the time of the test (8 December 2005), there were no such early termination criteria. Similar criteria, but with ‘test facility’ rather than ‘test apparatus’, had however been introduced earlier that year (6 October 2005) in the first BS 8414-2:2005 edition of the sister standard for cladding systems fixed to a structural steel frame (section 8.5):

Perhaps therefore, as a practical matter at least, such termination criteria would have been introduced to the BS 8414-1 test by December 2005. If so, then theoretically the test could have been terminated early because of flame spread above the test facility/apparatus or perceived risks. That the temperature gain at level 2 had not yet exceeded 600° C might then just reflect the fact that the system had failed before it had time to do so.

It does admittedly seem far-fetched to suppose that a BS 8414-1 test would be recorded on a BBA Certificate without any indication that the system had failed the test. Most probably there is an alternative explanation for why the claims that the system had limited fire spread and that it had passed the test according to the BR 135 criteria were removed from the 2010 amended Certificate. I think it would be important for the Inquiry to examine Test Report 220876 and to find out the reason for the retractions.

END OF ADDED SECTION.]

BBA 08/4582 Second Issue (2013)

BBA 08/4582 Product Sheet 1 for Kooltherm K15 received its Second Issue in December 2013:

There are important changes to the section on ‘Behaviour in relation to fire’. The product is still classified as Class 0 (England & Wales) or ‘low risk’ (Scotland), but the claim that it can be used in accordance with various specified paragraphs of the national building regulations is no longer in evidence:

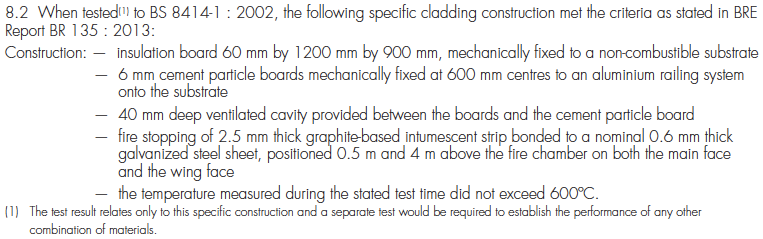

With respect to the BS 8414 test, the claim, last evident in the 2008 Certificate, that the system met the criteria of BR 135 is restored, but this time with reference to the 2013 edition:

The system is called a ‘specific cladding construction’ and the footnote makes it clear that the test result:

relates only to this specific construction and a separate test would be required to establish the performance of any other combination of materials.

Then, with regard to buildings over 18 m, where the previous certificates had directed that ‘advice should be sought from the Certificate holder’, the Second Issue permitted the product to be used only when it was:

incorporated in the construction defined in section 8.2

Two loopholes closed

The 2013 Second Issue of BBA 08/4582 permitted Kooltherm K15 to be employed in buildings over 18 m only if incorporated in the system defined in Section 8.2, with the 60 mm version of the product, 6 mm cement particle outer boards, a 40 mm cavity, and so on. Any other system would have to be subjected to a large-scale test to BS 8414.

Two potential loopholes had thus been closed:

- A user of the product could no longer point to Section 7.1 of BBA 08/4582 (2010) to show that it was ‘approved for use in accordance with the provisions of … [AD B2] 12.5, 12.6 and 12.7’.

- There was no longer any provision, as in Section 7.2 of BBA 08/4582 (2010), to seek ‘advice’ from Kingspan as to whether their product could be used on a high building.

At the end of Part 2 of this series, I showed a slide from a presentation by Steve Evans of the NHBC in which, referring to BBA 08/4582 and Kooltherm K15, he pointed (slide 7) to a:

Change in BBA certificate in late 2013 for most common product used on site restricted its use on buildings with a floor over 18m

If Evans is right that the revisions incorporated into the 2013 Second Issue of BBA 08/4582 had the effect of restricting the use of Kooltherm K15, then it follows that the terms of the First Issue had been allowing its use in systems other than the particular one that had been tested to BS 8414. In other words, one or both of these two loopholes had been open (assuming that there were no others).

If Kooltherm K15 actually was being used on high rise buildings prior to December 2013 on the basis of BBA 08/4582, apart from in the one tested construction, despite such use being contrary to the provisions of AD B2 12.7, then this would be an important key to understanding why more than one party apparently found it acceptable to install Celotex RS 5000 on Grenfell Tower, despite such use being contrary to 12.7. It seems to me that the Inquiry should investigate the approvals granted in this earlier period, and their basis. Was Kooltherm K15 in fact installed in alternative configurations? Was this on the basis of advice from Kingspan? Or, after the 2010 amendment, was justification for use of the product being found in the BBA’s apparent assertion that it fulfilled the requirements of AD B2 12.7? Or again, was it being used with no justification from either the Approved Document or the BBA Certificate?

the response from the bca

The changes made to BBA 08/4582 in its Second Issue seem to me to be highly commendable. Two potential loopholes had been closed, with the result that the product would now have to be used in accordance with the building regulations. One would have expected the BCA, whose remit is to enforce the building regulations as they are, not as they might prefer them to be, to advise that for buildings over 18 m, there were four ways of insulating buildings over 18 m:

- Use mineral (or glass) wool insulation;

- Use combustible insulation in a cavity in accordance with the concession in AD B2 12.7;

- Use combustible insulation in a configuration that had been tested successfully to BS 8414/BR 135;

- Conduct a new BS 8414/BR 135 test to demonstrate that a proposed system would fulfil the requirement for limited fire spread over the external walls.

Instead, as I described in part 2, the building control bodies took the view that:

the routes to compliance described in regulations were insufficient

I find it odd that the building control bodies would take a view of the matter. I can understand why the manufacturers of combustible insulation would be concerned, or purchasers who were trying to meet energy targets. But why should it be of concern to those engaged in building control? It must be part and parcel of their job often to have to frustrate the plans of designers and builders because of their burdensome duty of enforcing compliance with the regulations. Why were they so concerned in this particular case to relax the requirements?

The building control bodies clearly have an interest in the regulations, and I think it is quite legitimate for them to point out possible inadequacies and present proposals for change. But is it not quite unacceptable for them to, as it were, re-write the regulations on their own account?

A partial analogy may be found in those police forces that have expressed the view that possession of cannabis should be decriminalised. Clearly, they have much knowledge and understanding of the subject, and account should be taken of their view. But it is generally considered quite unacceptable for such a force to stop enforcing the law on its own account. The decision is for Parliament alone.

So here. The BCA could quite legitimately have made the case to Government for the addition of a Desktop Study route to compliance for external cladding systems over 18 m. If their view had been accepted, an Amendment could have been made to AD B2. Then everyone would have known what building regulations were in place. Instead we have a situation where AD B2 12.5 says, if interpreted normally, that system approvals require large-scale tests of the proposed system, while BCA TGN 18 says that whole systems can be approved on the basis of Desktop Studies of the probable results of a test of the proposed system, on the basis of data from tests of other more or less similar systems.

two alternative regulatory frameworks

The Approvement Document guidance for Fire Safety of external walls of buildings over 18 metres can be summarised as follows:

a) ‘Linear’ individual components route to compliance:

- Insulation materials and products should be of limited combustibility, as defined in Appendix A;

- External surfaces should be Class 0 or Euro Class B.

b) Alternative whole system route to compliance:

- The whole system must be tested to BS 8414 according to the criteria of BR 135.

The BCA TGN 18 guidance on the use of combustible cladding materials on buildings over 18 metres can be summarised as follows:

a) ‘Linear’ individual components route to compliance:

- All components must be of limited combustibility, as defined in AD B2 Appendix A.

b) Alternative whole system route to compliance:

- The whole system can be tested to BS 8414 according to the criteria of BR 135;

OR

- A Desktop Study can be undertaken to assess whether, in the opinion of a suitably qualified fire specialist, 3 the system would pass a BS 8414/BR 135 test if one were to be carried out.

The potential for confusion is clear. In practice, I think, manufacturers, designers and contractors will tend to adopt whichever set of guidance is more convenient for them. Omnis Exteriors, for example, must be looking to the Approved Document guidance to justify their view that Reynobond PE can be used safely, with the proviso that:

in high rise buildings class O rainscreen panels should only be used in conjunction with a non-combustible insulation material such as mineral fibre.

kingspan’s use of the bca guidance

Kingspan, on the other hand, in their Technical Bulletin on ‘Routes to Compliance’ (June 2016), point explicitly to BCA TGN 18 to justify their use of combustible insulation with combustible FR ACM panels.

In passing, they acknowledge the difference between AD B2 and BCA TGN 18, stating correctly (p. 5) that for the Linear Route, in comparison to AD B2 guidance, BCA guidance:

differs in that it explicitly states that … all major elements … should be of limited combustibility.

They describe the new Desktop Study route to compliance ‘offered’ (p. 5) by the BCA, and say that it has become a:

commonly adopted method of demonstrating compliance

An increasing number, they go on, of:

private and local authority Building Control Bodies (BCB’s), as well as structural warranty and insurance providers

are:

upholding the guidance contained within.

That is to say, these bodies are granting approvals, warranties and insurance based on Desktop Studies. Their number include the LABC, NHBC, LABC Warranty and Premier Guarantee:

What Kingspan does not tell its readers is that these bodies, which are progressively adopting the BCA guidance, include the main constituent members of the BCA, whose core is an alliance between the LABC and the Approved Inspectors. NHBC describes itself as the largest Approved Inspector, and its registered address (Office Locations tab):

appears to be the same as that of the BCA:

Moreover, in 2016 at least, the Chair of the BCA ‘Technical Committee’, which is presumably a misnomer for the BCA’s Technical Group which issues their Technical Guidance Notes, was the employee of NHBC, Steve Evans, whose presentation was referred to in parts 1 and 2.

Kingspan describe the BCA as an ‘industry group’:

but this is misleading, since its members are not involved in industry but in building control.

Diane Marshall, Head of Technical Services at NHBC, in her article of February/March 2017 in Building Control Journal, also referred to the BCA guidance as:

industry best practice guidance

So far as I can see, BCA guidance is not industry guidance but building control guidance. It is adopted and enforced by largely the same bodies that make it. It is rather, it seems to me, as if the police force were making the laws of the land. The BCA, or its leading members, seem to have gained a degree of autonomy in regulating the building industry. They appear to have attained a position where they can issue new guidance different to that of the Approved Documents, and then effectively allow the introduction of build-ups which are in compliance with their guidance but not with that of the Approved Documents, since they are the bodies that grant the approvals.

[continued in part 4]

Notes:

- See AD B2 Table A6, National Class, b. ↩

- The image is from a Channel 4 report at 1 minute 20 seconds. ↩

- As previously noted, the first edition of BCA TGN 18 required the Desktop Study to be carried out by one of 3 UKAS accredited testing bodies. The second edition of June 2015 relaxed the requirement to allow them to be undertaken by any ‘suitably qualified fire specialist. ↩

Andrew, thanks again for these incredibly thorough analyses. The section 13 of AD B Vol 2, somewhat threw me with its inclusion of limited combustibility as a path to a Class 0 rating, when I had understood it to be a pass of BS 476 Parts 6 (fire propagation) and Part 7 (surface spread of flame) as explained in most sources. And, as you say, it is slightly unclear, in reference to both ‘a material’ AND ‘the surface of a composite product’. Does it mean that the limited combustibility requirement applies only to the singular ‘material’ and the surface flame tests to the surface of composite products? Or is it that anything of limited combustibility would de facto pass both surface tests BS 476 Parts 6 and 7?

Whatever it is, it seems the resultant implication is that, to reach, as is stated, ‘the highest National product performance classification’, ‘Class 0’, you only need to pass surface flame tests, and NOT reach the, in reality, higher safety standard of limited combustibility. It almost seems like someone lobbied way back when this Class 0 highest UK rating was made, against limited combustibility being the sole way of achieving this highest rating, and insisted on the surface tests being an alternative means of reaching it. Do we know when Class 0 was first defined? Of course, the reality of this loophole greatly favours the manufacturers of the plastics PIR/PUR/phenolic insulation with its aluminium foil coating, and the composite cladding panels with their thin metal outer layers.

Good analysis of the BBA Agréments for Kooltherm, although patently false statements were made, they seem to have been corrected, but as you say, if people had understood them to be accurate at the time, installations may have occurred which were not in compliance with AD B Vol 2.

Regarding the ‘advisory’ statements made by the Building Control Alliance (GN 18/June 2014) in relation to the regulations (and subsequent ones by the National House Building Council), it is hard to believe for me that these were NOT made with the tacit or overt permission i.e. this was discussed in face to face meetings, of senior government and civil service officials. But as you say, the reality of this is chaos, where some architects and cladding designers (however much you might argue that they should be paying attention) still refer back to the Approved Document B, and are unaware or, at least, perhaps only partly aware, having been informed by word of mouth from others, of these new proclamations. One example of this chinese whisper effect, may be the requirement that is clear, in the BCA GN 18, that:’the client may instead submit a desktop study report from a suitable independent UKAS accredited testing body’

However if you look at this article in construction manager magazine, which uses the Portsmouth student accomodation featured on Newsnight as a case study:

http://www.constructionmanagermagazine.com/cpd-articles/cpd-facing-fi6re-regs-cladd6ding-pro5jects/

He states:

“The report must be backed with the results of testing by a suitable UKAS accredited testing body, and should make specific reference to any actual tests that have been carried out on the product. In addition to fire test data, the specialist will also typically require further information including plans, elevations, section and fire barrier details. Note that the specialist does not have to be UKAS accredited.”

So the GN 18 says the desktop study must be from a UKAS accredited testing body i.e. BRE or Exova (the merger of Warrington & Chiltern Fire), but now we have this industry figure saying the desktop study doesn’t have to be from them, just use some of their data- and would that be actual BS 8414 tests, or desktop studies? And then we have the further pronouncement from the NHBC in 2016, which stated that, as many Class 0/Euro Class B products have passed BS 8414 tests, all products in a cladding system may be Class 0/Class B, directly contradicting the BCA\’s 2014 pronouncement.

It seems that it is pretty clear, that industry cannot be trusted to make up or amend these rules, and government and the civil service must start to re-employ in house scientific expertise who can properly assess what is and what is not safe, without relying on industry, to frankly, bamboozle them in to making safety regulations that fit their own commercial preferences.

Thanks for this, John. On the point of whether a desktop study should be conducted by a UKAS body, this was a requirement of the first edition of BCA TGN 18 (2014), but not of the second (2015) – see my footnote 3 above.

Andrew

Aha, thanks Andrew, missed that. So no doubt gave in to more industry lobbying, and is it clear whether the studies can be based on previous desktop studies as well as full BS 8414 tests? Because if the former, given the quality of some desktop studies that we know of by Exova, and god knows what by these ‘independent fire specialists’, it can basically descend to ‘my mate said it was OK’ and we are back to where we started – which almost seems to be what the NHBC wanted to codify by stating, just let all Class 0/Euro Class B products be used, until they quickly backtracked after Grenfell.

The NHBC\’s 2016 document is really shocking (http://nhbcnews.co.uk/mvcs2/ImageGallery/NATIONAL%20HOUSE%20BUILDING%20COUNCIL/Clicks/02082016/K319_TechGuidanceNote.pdf). But of course these developments in 2015-6 cannot be used directly to explain what happened at Grenfell Tower, where the decisions about cladding were made I think in mid to late 2014. But I think they may give an indication of the type of culture that was prevalent a year or two before, but which didn’t manifest itself, so to say, until a little later. Andrew

I found an article previously (now can’t find link) that explained that desktop studies were proposed, because firms were simply not doing real BS 8414 tests, because of the expense, and presumably, by logical deduction, the implication was they were also often not meeting the AD B requirements of limited combustibility insulation. I’ve found a couple of interesting articles in Building Construction Design. In the first, from July 2015, Adrian Pargeter, Head of Technical and Product Development for Kingspan Insulation, describes the usage by industry of the BS 8414 system as ‘unrealistic’, presumably due to cost, and heavily promotes the desktop study and fire engineered approaches, describing the former as the ‘sensible route’, and the latter ‘a far better approach’.

https://www.pbctoday.co.uk/news/building-control-news/engineered-fire-safety/18944

The second article from January, 2017 is by Danny Phelan, national sales manager at Panel Systems. Interestingly he cites the 2013 update of Approved Document B, and claims that it:

http://www.buildingconstructiondesign.co.uk/news/its-no-tall-story-with-tall-buildings/

“gives clear guidance on the acceptable use of combustible materials within the external cladding system”

and “recommends either the use of materials of limited combustibility (or non combustibility in Scotland) for all key components”

Unless the 2013 version is difference from the 2013 version that is online, it does NOT say that all key components should be of limited combustibility. But he then does cite the GN 18 of the BCA which was the first document that I know that actually proposed this.

Very interestingly, he then states that “Questions have been raised by Building Control Bodies involved in high rise projects about the suitability of some insulation types. ” specifically citing PIR and PUR, but not phenolic.

Again, very interesting and either horribly prescient, or a reflection of what everyone was seeing in the years preceding Grenfell, but crucially an admittance that many in the industry had concerns just a few months before the disaster:

“There are a number of materials that offer limited combustibility and often these are specified. However, in some cases, materials that are less expensive or that offer better thermal performance have been selected at a later stage. This can compromise the safety of the whole building.

So the challenge facing specifiers and contractors is to find insulating materials which keep the costs of insulating a façade down, but which meet both thermal performance and fire safety requirements.”

Andrew,

Wonderful articles; I wait for the next.

One question puzzles me. How did National Class 0 come into being? It is not recognised by Ap. Doc. B as a British Standard. I’m sure I read that Class 0 material must still be tested to BS8414 to be considered MOLC. Just saying it was 0 is meaningless.

Kevin Ryan

kjgmryan@tiscali.co.uk

Thanks, Kevin. Class 0 has been around a long time. I was just looking at a paper from 1961 that was comparing it to the American surface spread of flame standard (ASTM E84).

It seems to be a class invented for lining materials, and is defined in the Approved Document. (AD B2, Appendix A.13).

You are right that being Class 0 doesn’t make something a MOLC. This is defined carefully in Table A7 of AD B2, and involves much tougher tests which I attempted to describe in an earlier post: http://theriveroflife.com/2017/06/23/grenfell-tower-was-the-cladding-legal-or-not-part-1/

Andrew