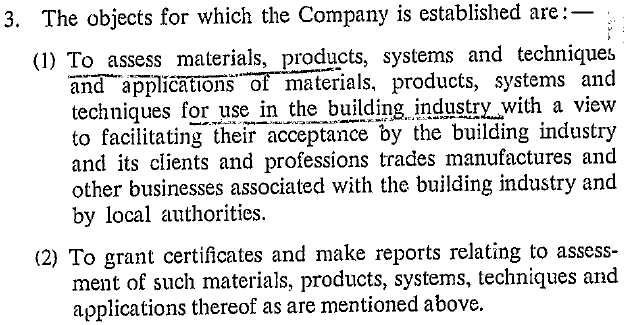

The British Board of Agrément is the leading British certifier of construction products and systems. It was originally named the Agrément Board, after a similar system pioneered in France by the CSTB (Centre Scientifique et Technique du Bātiment). The Director of the CSTB was invited (p. 62) to speak about that organisation at a special meeting of the Royal Institute of British Architects in 1963, and Geoffrey Rippon, the Construction Minister accepted a recommendation to establish a similar system in Britain. It was established in 1966 as a limited company controlled by the government, and was accordingly long referred to as a non-departmental public body. Its first two objects, as laid out in its Memorandum of Assocation, were to assess materials, products, systems and techniques for use in the building industry, and to grant certificates for them:

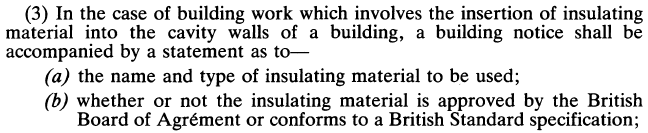

Under the 1985 statutory Building Regulations at 12(3)(b), the building notice for work that involved the insertion of cavity insulation had to state whether the material had been approved by the BBA or, alternatively, conformed to a British Standard specification:

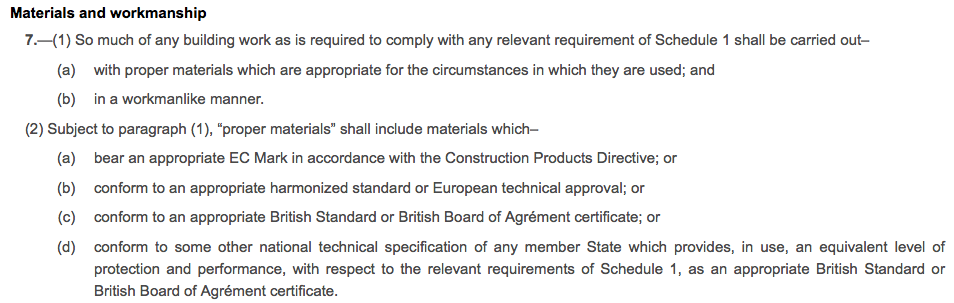

Under the 1991 statutory Building Regulations, conformity to a BBA Agrément Certificate meant that a construction material would be considered a ‘proper’ material under the Act:

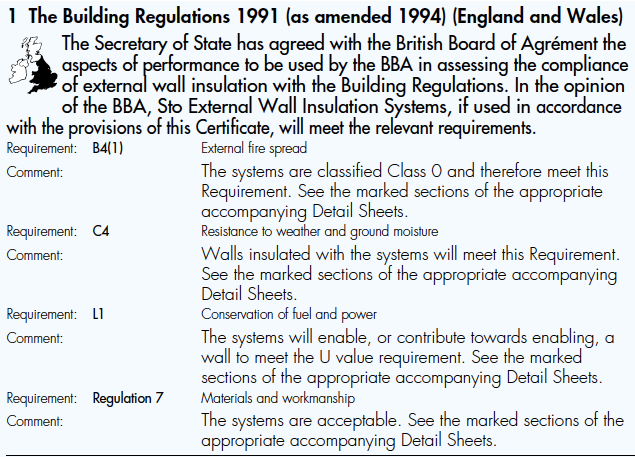

At this time, the BBA’s Agrément Certificates stated that the Secretary of State had agreed with the BBA which aspects of performance were to be used in assessing the compliance of a product of a particular type with the Building Regulations. For example, external wall insulation was to be assessed with regard to external fire spread, resistance to moisture, conservation of fuel and power, and materials and workmanship, as shown, for example, in Agrément Certificate 95/3132, issued in October 1995 for Sto External Wall Insulation Systems:

The BBA claimed that the Sto system met the fire safety requirement because it was classified Class 0:

as was also stated in the section of the certificate‘s Detail Sheet 2 that pertained to fire properties:

The BBA did not claim that the system had actually been tested to Class 0, merely that they had examined unspecified data relating to such tests:

What was this data? We are not told. Was it perhaps data from some other EWI system or systems that were tested to Class 0? A Parex EPS EWI system, for example, was successfully tested to Class 0 by Warrington Exova in 2010 (BS 476 part 6 test report, part 7 Report, Class 0 Summary Report).

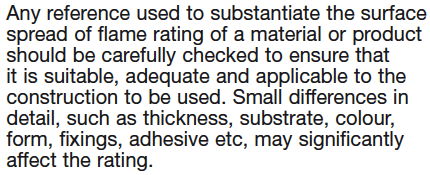

But this is a risky business. The current Approved Document warns (AD B2, Appendix A.16) that

small differences in detail

may significantly affect surface spread of flame ratings:

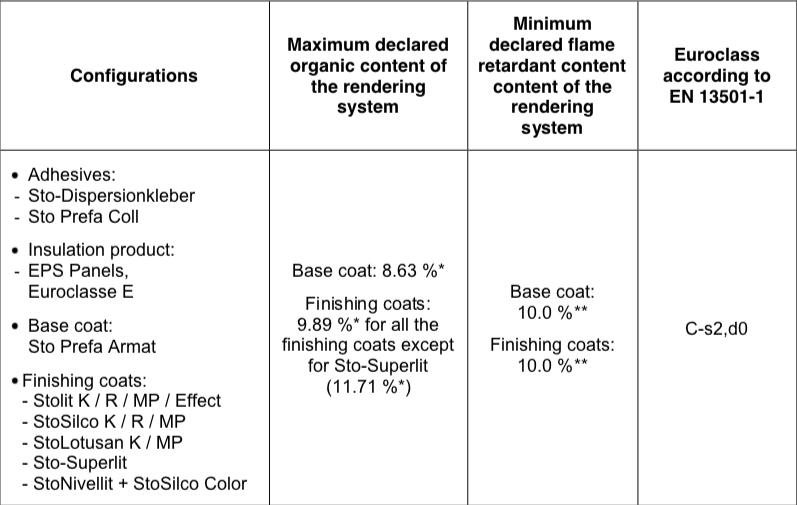

A European Technical Assessment issued in 2011 for a more recent version of Stotherm Classic, showed an EN 13501-1 Reaction to Fire rating of C-s2, d0:

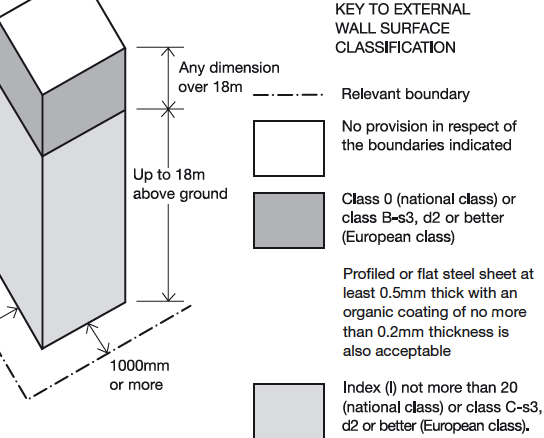

Since 2002, Euro Class B has been accepted in Approved Document B (now at Diagram 40) as an alternative to Class 0 for the external surfaces of walls above 18 metres. Class C is accepted only below 18 metres, where Class 0 is not required:

A Euro Class C is thus not sufficient to demonstrate a national Class 0. It may be compatible with Class 0, since Class B is generally considered more stringent than Class 0. But it falls short of equivalence with Class 0, and is not sufficient to establish it.

The Approved Document makes general provision for assessments to be carried out in lieu of tests (AD B2, A.1b):

…

but this should be a formal process, with any classification justified in an Assessment Report, signed by both assessor and reviewer (‘Guide to Undertaking Assessments in Lieu of Fire Tests’, Passive Fire Protection Federation, 2000, p. 7):

There is no reference to such an assessment report in the BBA certificate. So a question mark remains, to my mind, over the BBA’s claim of a Class 0 for this Stotherm Classic system.

The limited combustibility requirement for insulation

In the 1992 edition of Approved Document B, a ‘limited combustibility’ requirement had been introduced for insulation, with a concession for masonry cavity walls only:

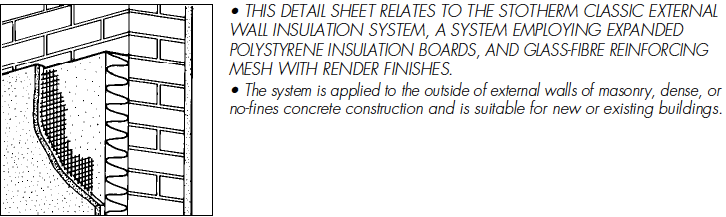

The Stotherm Classic system specified in Detail Sheet 2 of this 1995 Agrément Certificate was an Expanded Polystyrene (EPS) system:

These EPS boards incorporated a Flame Retardant Additive (FRA), but even one of Sto’s current range of EPS (FRA) boards has an EN 13501-1 Reaction to Fire Class of E, demonstrating their combustible nature.

The system should therefore have been restricted to use in buildings of less than 20 metres, according to the Approved Document guidance. But the BBA make no mention of the restriction, but instead deliberately flouts it, so far as I can see. They even portray the system being employed on residential tower blocks on the front page of the Agrément Certificate, with no indication as to whether the version employed incorporated combustible insulation (Detail Sheet 2) or non-combustible (Detail Sheets 3 and 4):

For the approval they grant to use this combustible insulation system at any height, the BBA apparently rely on the following paragraph in AD B2 (1992), 12.7, which refers to advice given in a BRE Report, published in 1988, on external thermal insulation for walls of multi-storey dwellings:

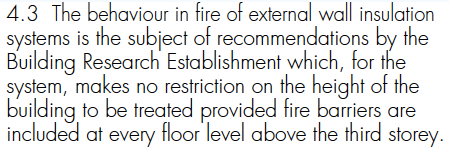

BR 135:1988 does indeed give advice (p. 6) on systems with EPS insulation, glass fibre reinforcement and render finish, and makes no mention of a height limitation:

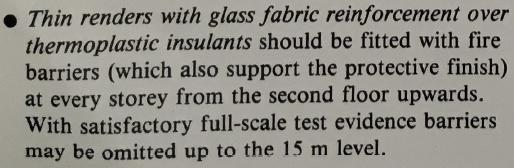

Its specification, that fire barriers should be fitted at every storey from the second floor upwards, is similar but slightly more stringent than that of the BBA Agrément Certificate:

[ADDED 22 April 2018

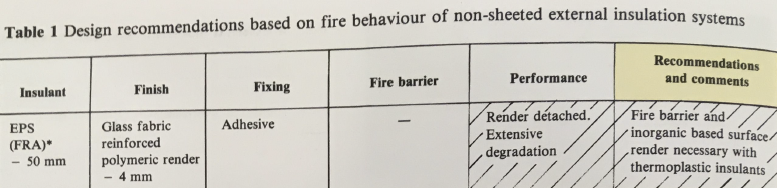

A closer examination of BR 135 1988 casts doubt on whether it really gives support for the use of this Stotherm Classic System above 18 metres. Table 1 shows the systems tested, results, and recommendations. The first system tested had a polymeric render, which detached in the fire, resulting in extensive degradation of the system. The BRE recommended (p. 4) therefore the use of an inorganic based render:

… inorganic based surface render necessary with thermoplastic insulants …

EPS is thermoplastic, so it follows that BR 135 1988 advises that an inorganic based render be employed with it.

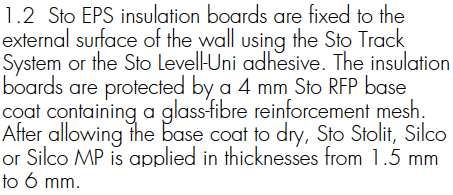

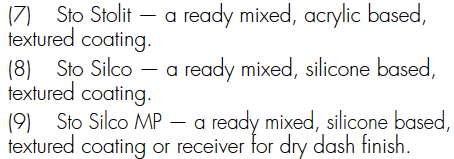

The StoTherm Classic system uses one of three renders, Sto Stolit, Silco, or Silco MP:

All three have an organic polymer base:

It seems to me therefore that BR 135 1988 does not provide a basis for approving the use of StoTherm Classic on high rise buildings.

END OF ADDED SECTION]

But, in any case, the Approved Document (12.7) gives no indication that its limited combustibility requirement for insulation can be disregarded on the strength of the BRE’s advice:

The height limit on combustible insulation is expressed as a requirement, whereas there is no requirement to follow the BRE’s advice. I do not yet see how the latter could override the former, even if BR 135 1988 did support the use of a system like StoTherm Classic on high rise buildings.

What do you say, BBA? Do you stand by Agrément Certificate 95/3132, which you issued in 1995, and which apparently contradicted the Approved Document guidance? Or would you now agree that you were mistaken in approving the use of Expanded Polystyrene insulation on external walls on residential high rise buildings?

Andrew Chapman